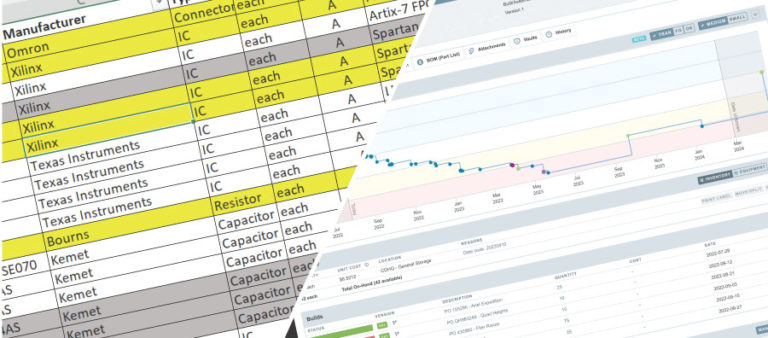

It is still common practice for many firms to manage their inventory and supply chain operations with some form of spreadsheet. Often, these spreadsheets are home-grown and built from on-the-job lessons learned by managers and engineers in the company. These spreadsheets certainly can be ‘good enough’ at managing Material Resource Planning (MRP) activities. On the other hand, there are several reasons for making the move to MRP software.

In-House Spreadsheet Solutions Increase Cost and Maintenance

Assembling a comprehensive and effective MRP system from spreadsheets is no simple task. The architects and maintainers of such systems need to be domain experts and spreadsheet software experts. The eventual solution is often brittle and costly to maintain and evolve as the business grows or the operating environment changes. Purpose-built MRP software like Aligni is designed from the ground up to be effective and efficient with integrated best practice guidance allowing your team to focus on efforts that provide more value to your customers.

The Right Information, Right Now

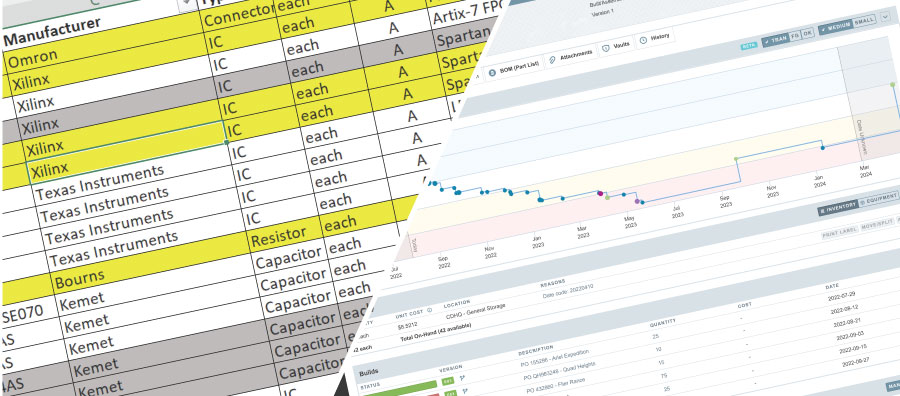

When compared with spreadsheets, MRP software offers several distinct advantages for complex inventory processes with regards to data integrity and availability. Software solutions reduce the reliance on human recordkeeping and data input. This helps reduce potential errors and wasted time. Keeping the information in a database makes for reliable storage and faster retrieval. Companies can instantly review inventory levels and more efficiently plan for demand rather than manually collecting information and trying to keep spreadsheet files updated.

A Single Source of Truth

In addition to improving inventory accuracy and efficiency, MRP software also offers advantages when sharing information across departments. With a cloud-based system like Aligni in place, data can be quickly and accurately shared among stakeholders throughout the organization. An MRP system’s database eliminates the need for synchronizing multiple spreadsheets by hand. The system also helps keep everyone on the same page while reducing errors caused by outdated information.

Getting More out of Your Data

For manufacturing operations that require a large number of parts, highly specified components, a list of vendors, or any combination of these, investing in software purpose-built for Material Resource Planning is superior to relying solely on spreadsheets. MRP systems are designed to manage the large amounts of data operations. They also offer methods to utilize this data to find inventory efficiencies and lead to proactive purchasing strategies that are beyond what could be managed with two-dimensional spreadsheets. With MRP software in place, manufacturers can reduce costs and increase productivity while better managing their material resources.

If you’re looking to manage your MRP processes more efficiently and are ready to give up the spreadsheet, sign up for Aligni MRP today!

Start your 30-day free trial

Helping You Make Great Things…Better.