MRP

Streamlining Supply Chain Management with Aligni MRP

Managing the complexities of keeping a manufacturing operation stocked with the parts they need is difficult. Success lies in the details and staying in front of all the timelines.

Trying to do this with spreadsheets can actually make it worse. These files are difficult to share across an organization. This makes it almost a full time job to make sure the data is correct – and that needs to happen before real purchasing decisions can be made.

Using a Material Requirements Planning (MRP) system like Aligni MRP for supply chain management offers several benefits that help streamline operations and improve overall efficiency. Aligni is built on a database that offers centralized access to every department. That means everyone is working off the same information. The software also manages timelines and updates as changes occur, keeping everything current.

We’ve broken out the key areas where moving to an item master-based inventory and vendor management system like Aligni MRP can provide the greatest results.

Improved Inventory Management

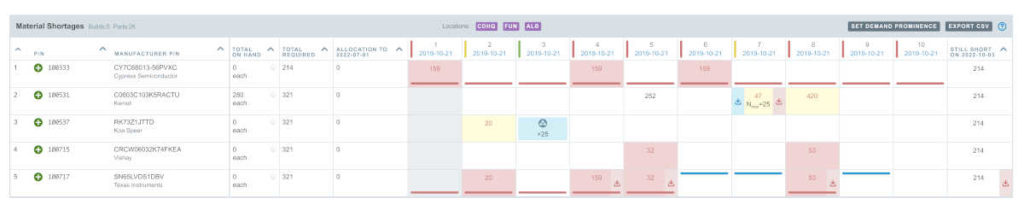

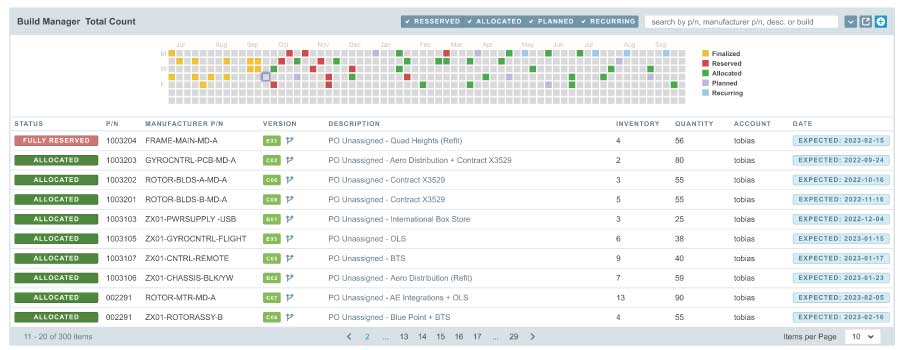

Aligni MRP enables better control and optimization of inventory levels. By providing demand estimation capabilities, material shortage reporting, and lead time management all from a single database, Aligni can ensure the right materials are available at the right time. This helps reduce excess inventory and associated carrying costs, minimize stockouts, and avoid production delays.

Enhanced Demand Planning

Aligni is built with demand forecasting tools that uses the company’s own data to more accurately predict future demand. This allows manufacturers to plan production and procurement activities based on real-time and accurate demand data. With improved demand planning provided by Aligni, supply chain managers can optimize inventory levels, align production schedules, and ensure on-time delivery to customers.

Efficient Production Scheduling

Aligni MRP provides visibility into the availability of materials, production capacities, and lead times. This enables manufacturers to generate optimized production schedules that account for material availability, minimize idle time, and improve production efficiency. Efficient production scheduling helps meet customer demand, reduce production bottlenecks, and maximize resource utilization.

Streamlined Purchasing Process

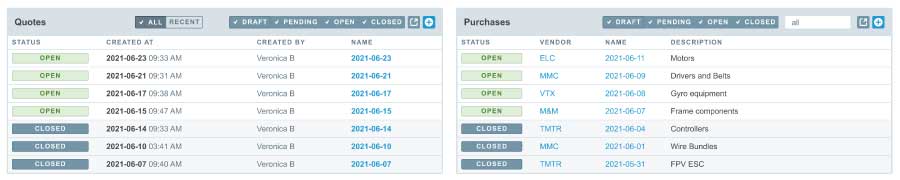

Through the ActiveQuote vendor management system, Aligni MRP takes the purchasing process to the next level. By integrating suppliers within its vendor portal, Aligni helps facilitate seamless communication and collaboration with suppliers. RFQs and purchase orders can be generated within the system and posted to vendors via email. Vendors are notified when these requests become available electronically and can post their replies to the same system. Historical purchasing data is also retained for future analysis. This streamlines the purchasing process, reduces manual effort, and ensures timely procurement of materials. It also improves supplier relationship management and can help to negotiate favorable terms and pricing.

Accurate Material Requirements Planning

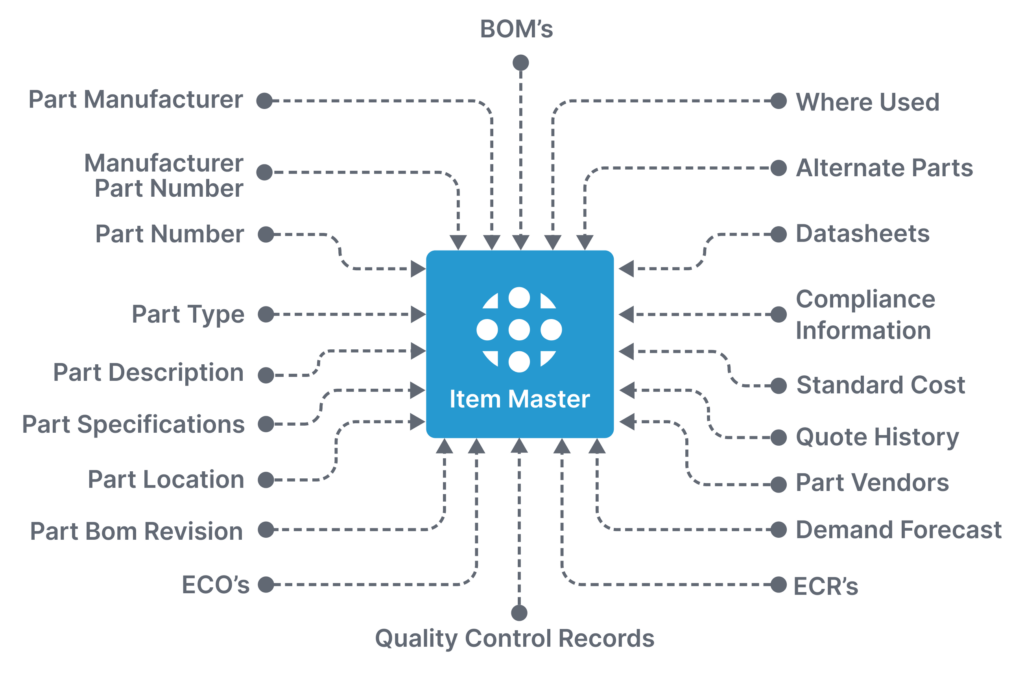

Aligni MRP uses bill of materials (BOM) data to calculate accurate material requirements. This eliminates manual calculations and reduces the risk of errors. These BOMs are developed by the product engineers and maintained through internal ECM and other processes. Keeping the data within one item master database ensures correct part and material data across departments. Accurate material planning ensures that manufacturers have the necessary materials in the right quantities, minimizing waste, reducing excess inventory, and improving cash flow.

Explore what Aligni can do for your organization

Inventory Visibility and Control

Instead of searching through several files or competing information systems, Aligni MRP acts as the hub for part and material management. It provides visibility into inventory levels, production progress, and order statuses all from its item master database. This enables supply chain managers to monitor operations, identify bottlenecks, and take proactive measures to resolve issues in one place. With improved visibility and control that Aligni provides, organizations can make informed decisions, enhance responsiveness, and address potential disruptions promptly.

Interdepartmental Integration and Collaboration

The Aligni MRP system facilitates effective communication by providing a platform where departments can share information, updates, and feedback. Design teams can work together with manufacturing, engineering, and procurement teams. This can be done simultaneously within the Aligni platform. Aligni MRP’s item master database serves as a central repository for all product-related data, including design files, specifications, BOMs, and change orders. Collecting all this information in one system ensures all departments have access to the most up-to-date and accurate information. Aligni helps eliminate data silos and reduces the risk of errors caused by outdated or conflicting data stored locally or across the organization.

Take the Next Step with Aligni

These are just a small set of examples that illustrate a database driven system can bring efficiency to a supply chain operation. By leveraging the capabilities of Aligni MRP systems, organizations can optimize inventory levels, improve production planning, reduce costs, enhance customer satisfaction, and increase overall supply chain efficiency. Aligni provides the necessary tools and capabilities to streamline supply chain management processes and adapt to changing market demands.

Ready to take the next step in managing your supply chain operations? Sign up online with Aligni today!