PLM

Specifying Components with Aligni PLM

In today’s manufacturing landscape, almost nothing is made completely in-house. Developing new products often involves sourcing and selecting parts and materials that will make up the final product. When there’s a great deal of components to be sourced or the parts needed have to satisfy precise requirements, certifications, or other details, it’s in the product engineer’s best interest to use software designed specifically to manage the part specification process. The software best equipped to perform these functions is product lifecycle management (PLM) systems.

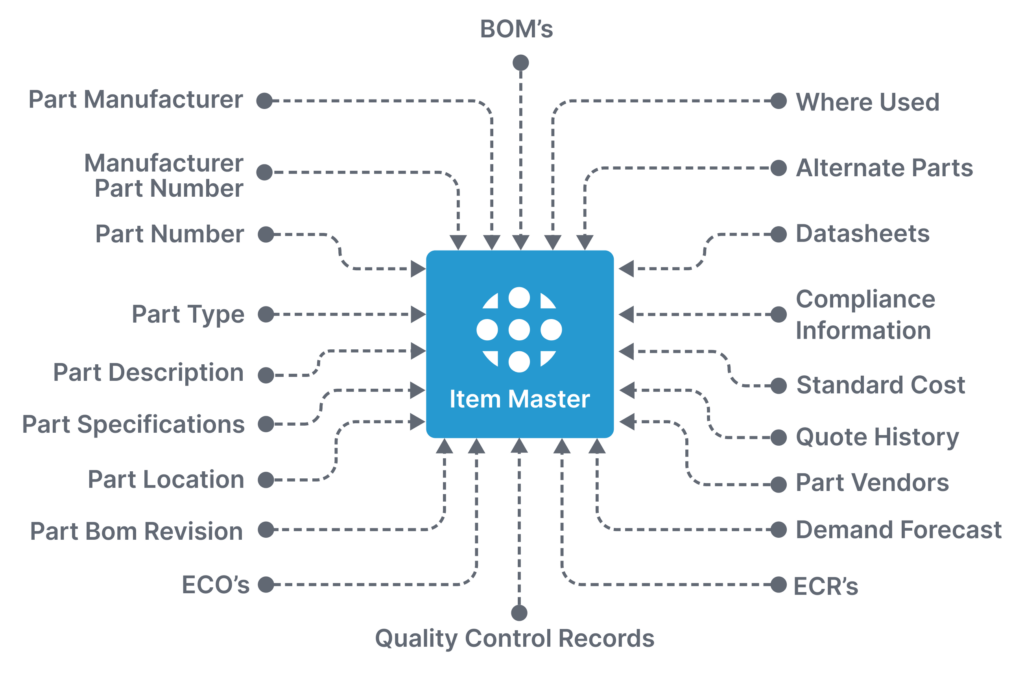

Software like Aligni PLM is purpose-built to streamline the sourcing and selection process. Its tools are designed to support the process at nearly every stage of the process. The functionality that makes it possible is Aligni’s item master. This database stores parts and materials information during the process. The item master makes it easy to manage the large amounts of data collected. It also functions as an archive of the process which can be reviewed and reused for future activities.

Getting Into the Details

To explain how Aligni PLM is a resource during the specifying process we’ve broken out the common steps and where Aligni can make an impact, below.

1. Identify Component Requirements

The first step is to identify the specifications of the components needed for the product. This may include requirements for size, weight, power consumption, performance, and other factors. Looking at prior builds of similar products within Algini PLM can help save time in the process by reviewing past decisions and results.

2. Research Components

The next step is to research potential electronic components that meet the identified requirements. This may involve reviewing manufacturer data sheets, consulting with suppliers, and conducting tests to evaluate the performance of different components.

Aligni PLM is designed to store component information from not only prior builds but materials the company already has on-hand. Searching through this database of parts and data can help engineers reduce time to market. It reduces redundant searches, too.

3. Evaluate Components

Once potential components have been identified, the next step is to evaluate them based on various factors. These factors may include cost, availability, performance, and quality. This may involve comparing different components to determine which one is the best fit for the product.

Recording the results of the evaluations in a searchable database within Aligni PLM reduces errors and makes comparing the data much easier. The process makes the data easily available to other members of the organization. It prevents information from being locked in spreadsheets or other files held on personal folders or computers.

4. Document Component Specifications

Once a component has been selected, it is important to document its specifications, including its part number, manufacturer, and relevant performance characteristics.

This functionality is built into Aligni PLM where the information can be used to create a bill of materials (BOM) for the product. With every detail of the specifying process saved within the Aligni item master database, alternate parts can also be indicated. PLM systems contain the necessary information needed to source other parts, should the selected ones become unavailable, or requirements change.

5. Track Components

It is important to track the use of parts throughout the product development process to ensure that they are used correctly and consistently. This is where using a product lifecycle management (PLM) system to track component usage and inventory shines. Its database and ease of access to usage data puts it well above trying to do the same with spreadsheets or other processes.

6. Verify Component Compliance

Finally, it is important to verify that the selected components comply with relevant industry standards and regulations, such as RoHS and REACH. This can be done by reviewing supplier documentation. Performing tests to ensure that the components meet the required specifications may also be needed. Using a PLM system to track this documentation and test data makes short work of verifying part compliance at later stages. The system also makes that data available for other projects later on.

The above were just a small sampling of what can be done with a PLM system like Aligni. These systems help make the parts specification process more efficient when developing new products for production.

Explore what Aligni can do for your organization

Even Greater Benefits in Store

Many firms have found more ways to find efficiency in the process of specifying components by using PLM systems as their central repository for part and build information. A purpose-built management system can ensure that manufacturers and product developers select the best components for their products. It can also help meet industry standards and regulations.

When you feel it is time to better manage the part specifying process, it’s also time to sign up online for Aligni PLM.

Start your 30-day free trial

Join over 4,000 teams that are managing their manufacturing with Aligni.