The Purchasing Tools You Want Connected to the Data You Need

Aligni empowers engineers and buyers to make informed decisions on product builds and purchases.

With tools like the Vendor Portal, communication with vendors is optimized and vendor relationships are streamlined. Learn more about how Aligni integrates its systems and tools for quoting and buying with PLM operations to seamlessly integrate the purchasing process with product engineering and production.

Aligni Integrates the Purchasing Process with Product Engineering and Production

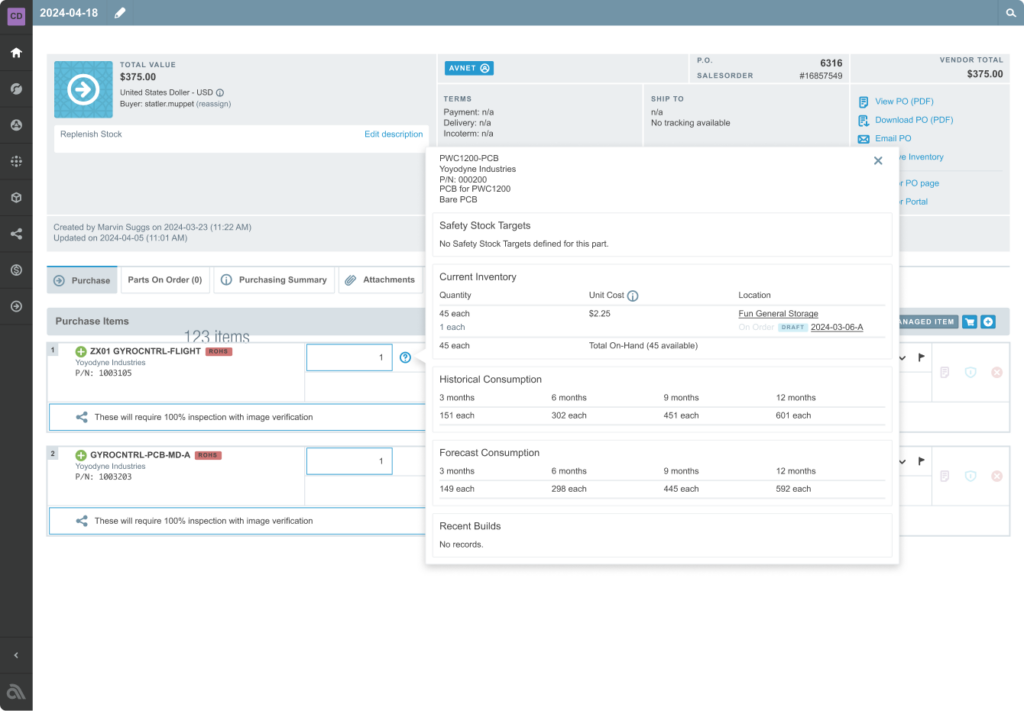

Aligni allows you to build RFQs directly from parts lists, builds, and shortage reports. As BOMs, builds and purchasing are housed within one system, transferring over the necessary information is easy. Storing all part and purchasing data in Aligni’s shared database vastly reduces transcription errors, selecting the wrong vendors and the use of out-of-date information in the RFQ process.

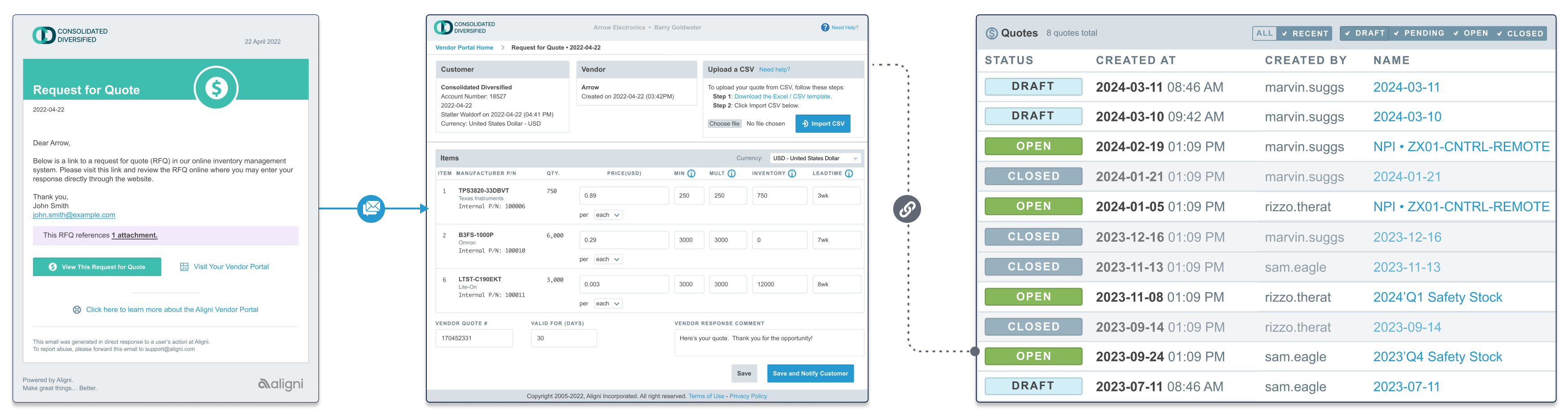

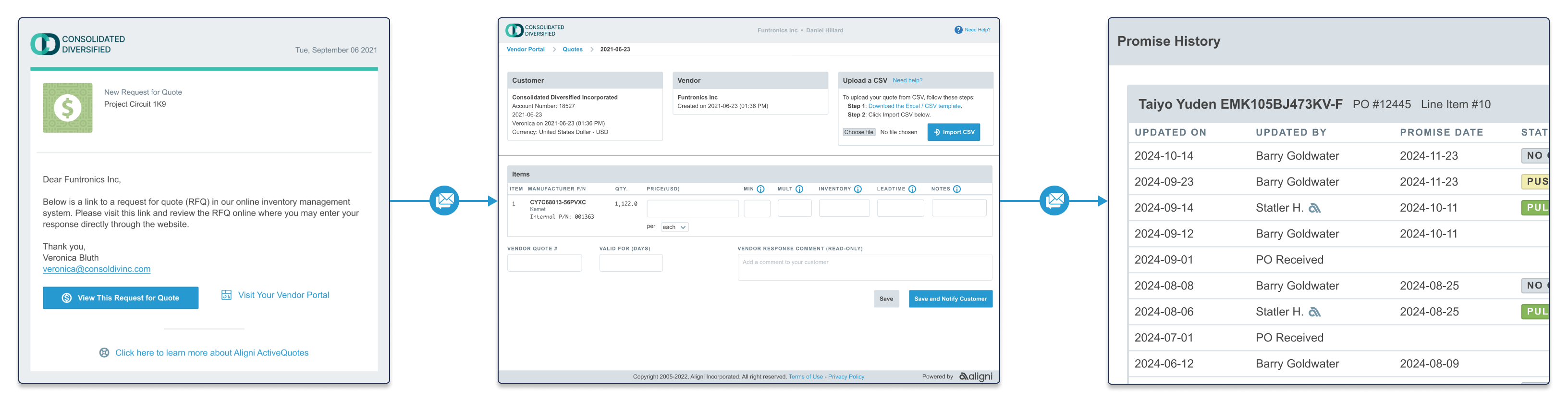

No more working between your email system and PLM system to manage quotes. Send RFQs and POs to vendors from within Aligni. Combining vendor communication with RFQ creation and management reduces unnecessary steps moving between applications. It also reduces the errors and overlaps that also develop from juggling the buying process across two systems.

When the purchasing process is housed within the same system as product lifecycle management, changes during the buying process automatically update the information used by others in the system. This reduces potential human error in moving data to unconnected applications. It also increases the speed of distributing information across workgroups and departments, helping to create a more responsive and streamlined organization.

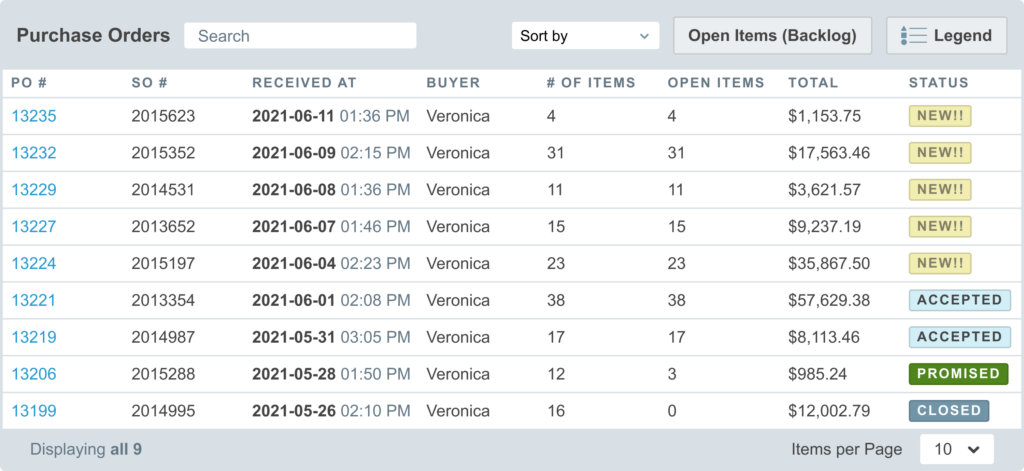

Learn more about Aligni’s Vendor Portal and how it manages RFQs and POs.

Aligni Helps Streamline Vendor Relationships

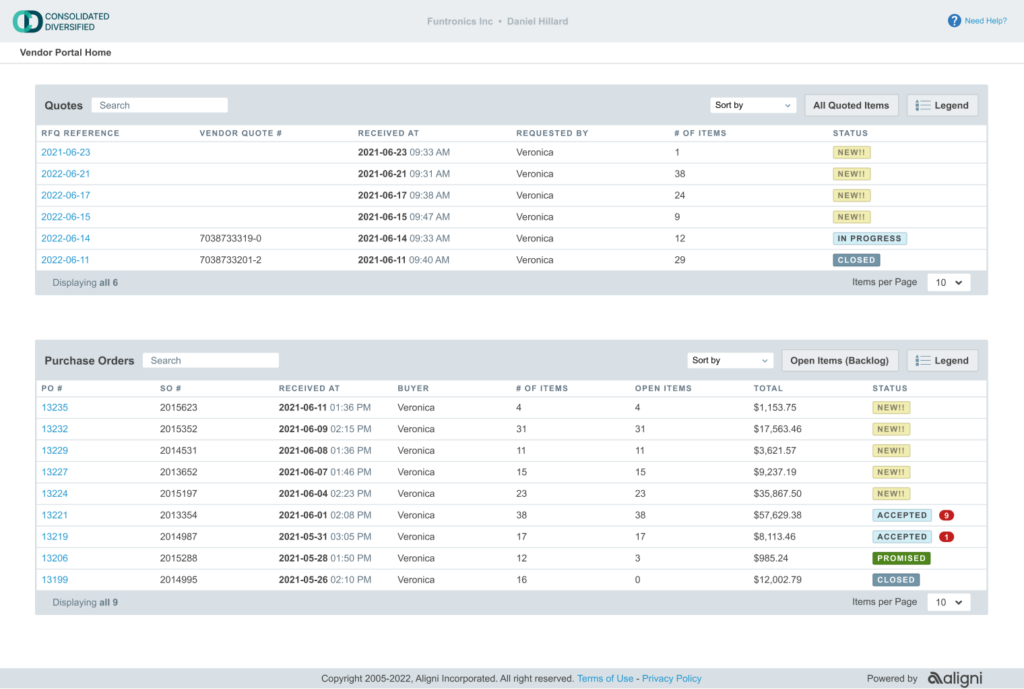

Directly communicate with vendors through Aligni’s Vendor portal. The Vendor Portal is highly integrated with Aligni’s other functions like inventory management and demand planning. This integration reduces the issues that stem from working between a PLM system and an email system to manage purchases. It also centralizes communication if there are more than one buyer within the organization – everything is one place.

The Vendor Portal provides greater benefits by providing vendors the ability to directly key in quotes into Aligni. It also allows vendors to update delivery times once purchases are finalized. This reduces the potential for incorrectly typed in information by buyers. It also increases the speed of reply from vendors, as buyers don’t have to wait for a quote to be generated and sent through email or other means.

Aligni knows a communication system is only useful if the right people use it – that means reducing the hurdles vendors face in operating the system. To help, Aligni has built its Portal without requiring vendor accounts – vendors don’t have to hold any credentials. Combined with the ability to be alerted to new RFQs quickly, this helps encourage adoption and reduce vendor resistance.

Learn more about Aligni’s Vendor Portal

Aligni Helps Make Your Historical Purchasing Data Work for You

Algini retains purchasing information and makes it available in several areas throughout the system. This data is made available during the part selection process, the RFQ process and other locations. In the face of historical pricing moves and availability experiences, having this historical purchasing information on hand helps buyers and engineers to be proactive in selecting the right parts and vendors. The data offers further value in setting up and updating safety stock limits as trends are identified.

The Vendor Portal retains prior conversations, RFQs, POs, and other aspects of the purchasing operation. With stored communications and results, it allows companies to reduce siloed interactions while making it easier for others to understand how to best work with vendors.

Aligni also makes this data available to other departments within the organization. Sharing pricing, delivery and vendor information from one location makes sure everyone in the organization is working off of the most up to date information. This helps make sure decisions on parts and which vendors to use won’t be made on outdated information or misguided preferences.

Learn more about Aligni’s Vendor Portal capabilities

Start your 30-day free trial

Helping You Make Great Things…Better.