Managing Builds Is Easier When Sales Demand, Inventory, and Production Are Integrated

Aligni MRP is designed from the ground up to reduce the complexity of managing multiple product builds through its advanced product and inventory management tools.

Aligni simplifies production build management by seamlessly connecting inventory needs with production demands, streamlining the process. Engineers benefit from improved part selection and management, driven by interconnected inventory and builds within Aligni’s system. When overseeing multiple builds, Aligni makes it effortless with its tools designed to remove complexity and enhance efficiency.

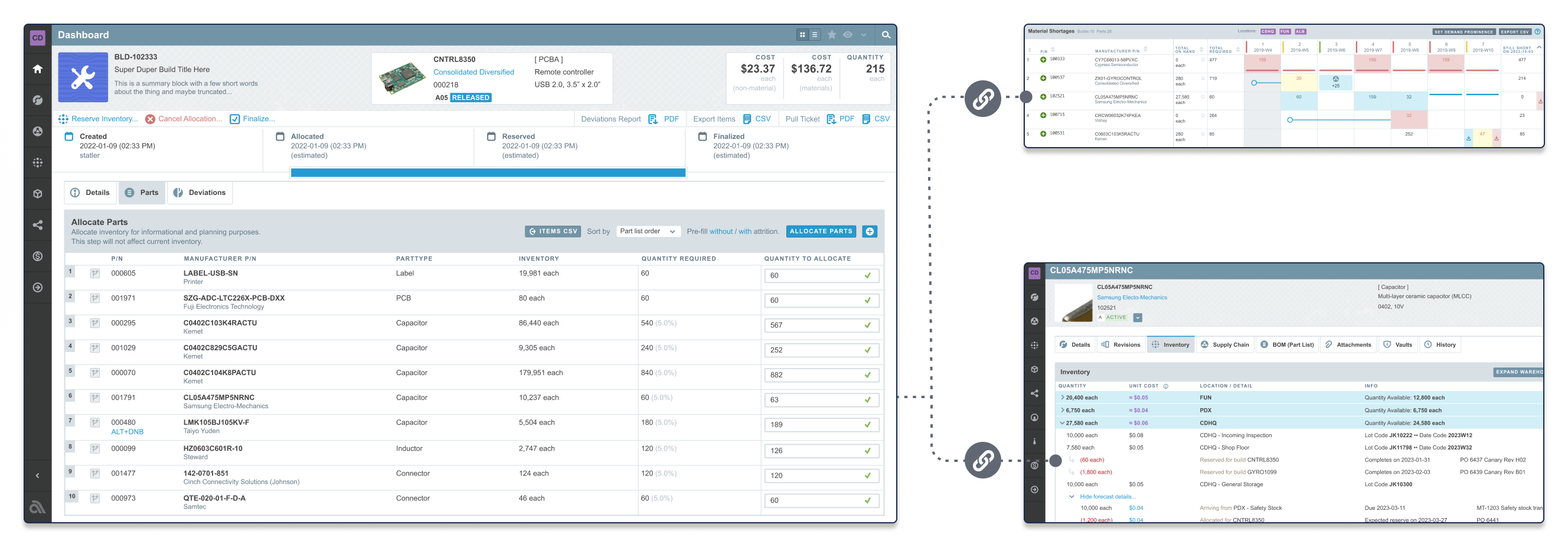

Aligni Streamlines Build Creation and Their Effects on Inventory

In many organizations, product parts lists are kept separately from inventory allocations for production. This could stem from engineering using a different system than operations or the information could merely be saved in spreadsheets. In Aligni, both systems are combined. This provides advantages in not only conveying information between departments but ensuring quantities on-hand meet production needs.

In Aligni, build inventory requirements are pulled directly from the product’s bill of materials. This integration reduces translation errors and omissions of important information that typically stem from transferring data between programs or from file to file. It also ensures the specified parts are selected for the build and the best vendors to source them.

Inventory management and BOMs are also highly integrated within Aligni. Part availability for upcoming builds is automatically calculated from inventory on-hand. Builds can also be built in Aligni without immediately allocating resources. This reduces issues during the planning process and misrepresenting materials needs in the process. That means when builds are generated, a manager knows immediately the state of parts on hand for the batch and shortfalls can be immediately identified – well before the build goes into production.

Learn more about build management and bills of materials in Aligni

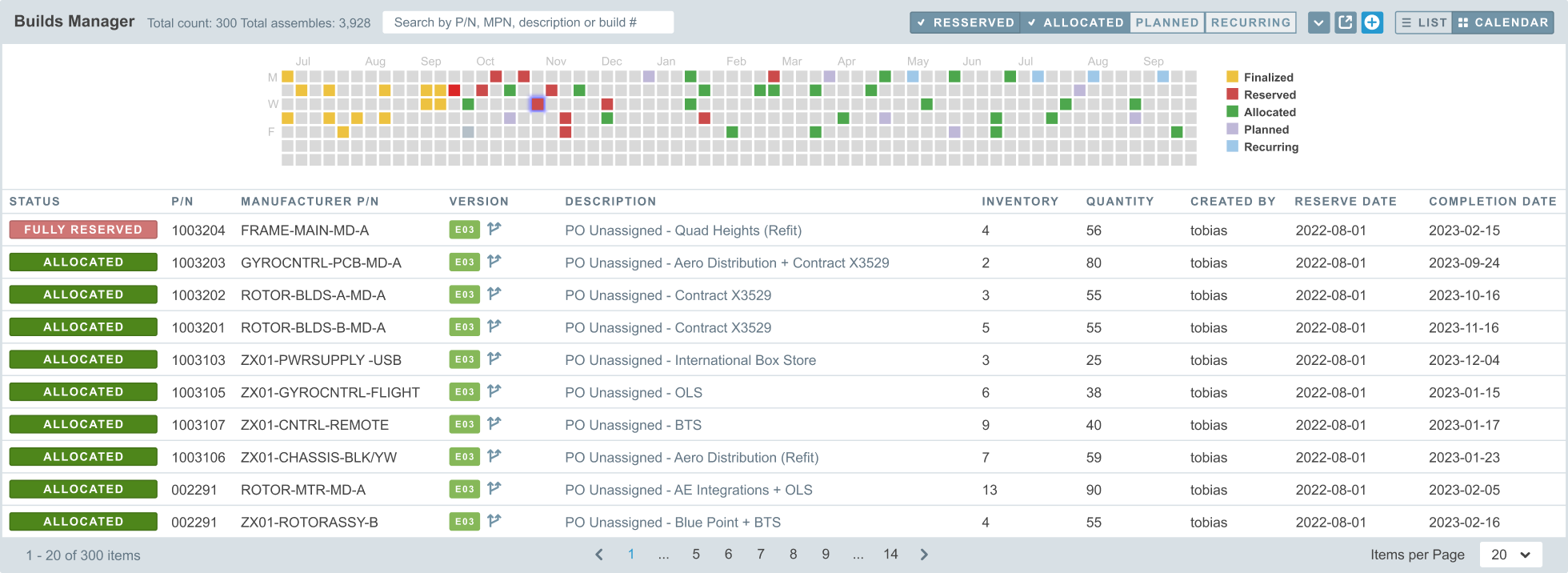

Aligni Takes the Complexity Out of Managing Multiple Builds

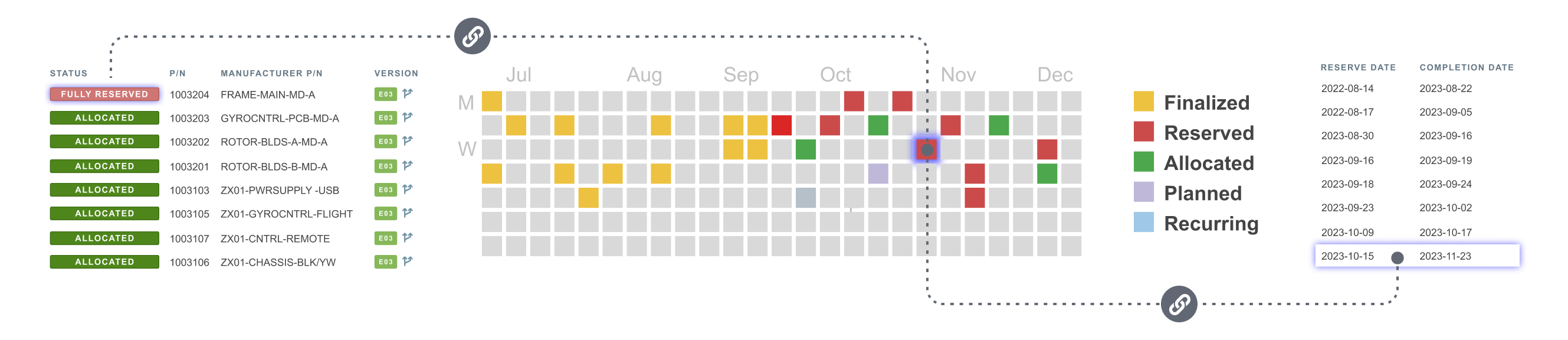

Whether overseeing recurring, one-off or a combination of job types, Aligni provides the tools to effectively manage production builds from one location. Aligni’s Build Manager dashboard is designed to provide an intuitive and cohesive view of all builds within the system while highlighting the important details that make up each’s status.

Aligni’s Build Manager dashboard lists every build in the system and each batch’s inventory allocation status. To help managers determine where to focus their attention, Aligni color codes each build to its inventory status. Builds can be sorted by several factors on the Build Manager dashboard. This helps managers identify the issues that matter most to their processes and provide that information to more effectively plan production operations. This ability helps locate pressing issues and prioritize attention across the entirety of builds within the system.

At the top of the Build Manager dashboard, Aligni graphically displays each upcoming build by date in its build calendar. Each build in the calendar matrix is color coded by their readiness for production. The build calendar helps managers quickly understand the distribution of builds over time. Managers can use this to identify and reduce overscheduling and inventory-related downtime events in the production schedule. It also helps buyers plan purchase orders more efficiently.

Learn more about managing builds and the Aligni Build manager

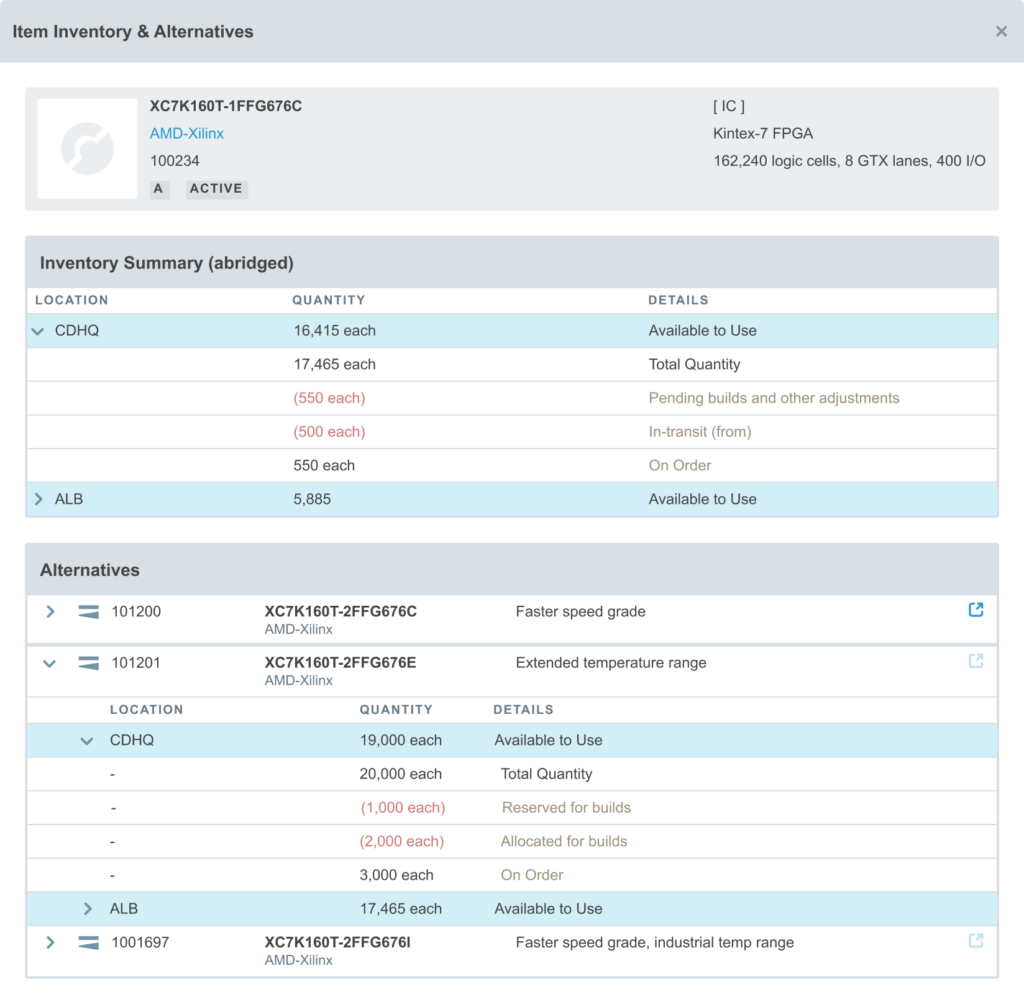

Better Part Decisions from Interconnected Inventory and Builds

Through its item master database, Aligni brings together data from multiple departments. It also makes that data available to help better decision making across the organization.

For product engineering, product bills of materials, builds and company inventory information are interconnected and searchable in Aligni. Use Aligni’s inventory integration to analyze parts lists and simplify builds by exchanging hard to source components with commonly used parts. SKU reuse helps reduce inventory part counts while helping the company utilize proven parts and vendors over sourcing new components.

The combined data in Aligni helps production and supply chain departments fully understand part needs against inventory on-hand. This leads to more proactive management of upcoming builds and reduced downtime events due to inventory shortages. Aligni’s build screens also list available alternate part options and the quantities in stock. To sidestep out of stock issues, purchasing and operations managers can keep production on schedule by modifying builds with approved alternatives.

Learn more about Aligni’s material shortage reporting capabilities

Start your 30-day free trial

Helping You Make Great Things…Better.