Master Bills of Materials Management

Aligni MRP has the tools to make sure your BOMs are built properly, cost effectively and shared securely.

Aligni streamlines BOM creation by centralizing data in a unified item master database, empowering engineers to make informed decisions on parts, materials, and vendors while efficiently tracking changes. Additionally, Aligni’s Vaults feature enhances integration and securely manages information sharing with vendors and external organizations, protecting sensitive data.

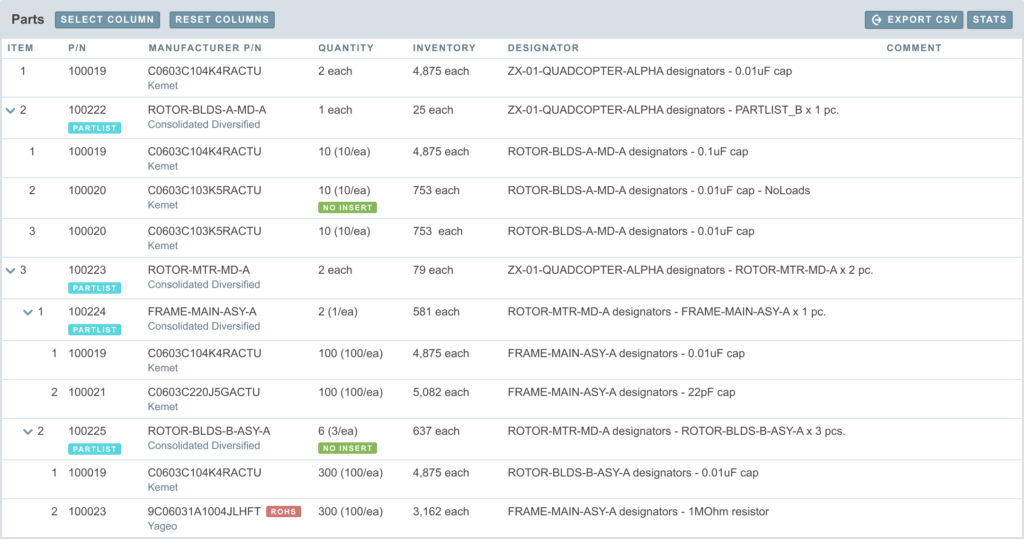

Building BOMs Is Easier When Data Is Integrated

When a company uses Aligni, it empowers its product engineers with next level information access. It shares what parts are currently in stock over ordering new or different components. This ability is made possible through Aligni’s robust database that’s shared across the entire organization. With the company’s data collected in one location and highly accessible, it’s now easier for engineers to see what inventory is available and what is not, saving the time and effort involved in sourcing new components. They can also see current pricing to help achieve project goals.

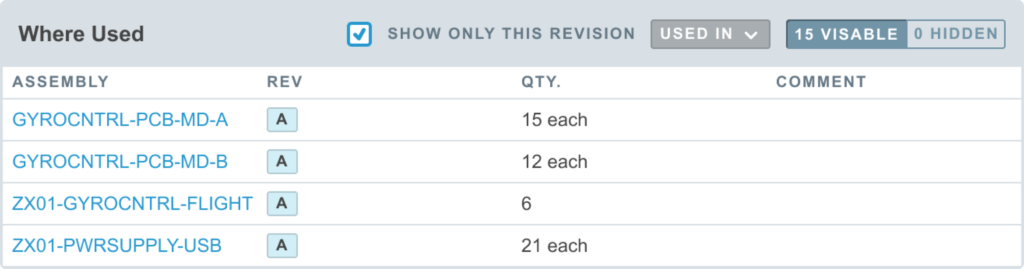

Further, Aligni reduces the time and effort required to find where-used information throughout the organization’s parts lists. When BOMs are managed in Aligni, finding all the places where parts are used is as simple as looking the part up. Understanding where and how often common parts are used can reduce overall SKU counts and unnecessary sourcing activities. Aligni helps businesses skip the hassle of digging through old files and product data to piece together all the places parts are used, through its extensive search functionality.

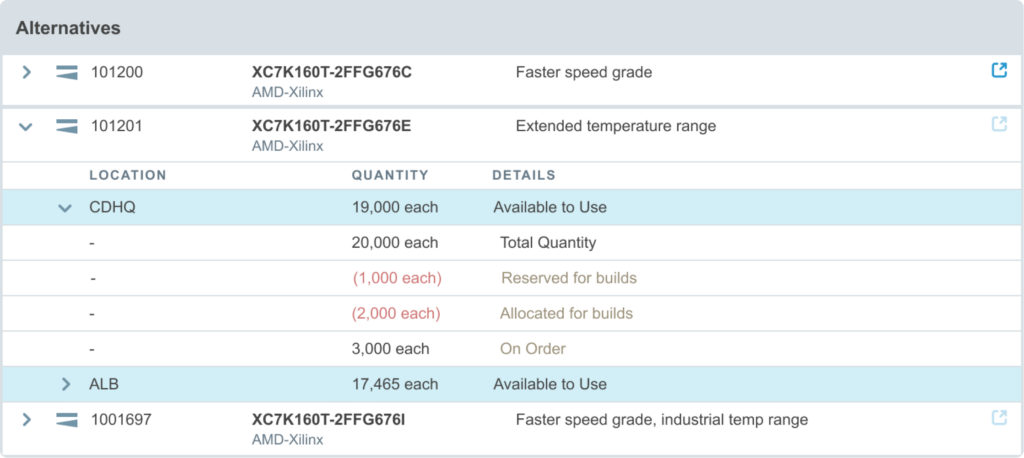

When the ideal part is unavailable, Aligni provides the information required for engineers to make the safe choice from a list of approved replacements. Aligni’s alternate parts management abilities saves time and reduces costly issues stemming from specifying similar but incompatible parts.

Learn more about Aligni BOMs and its item master database

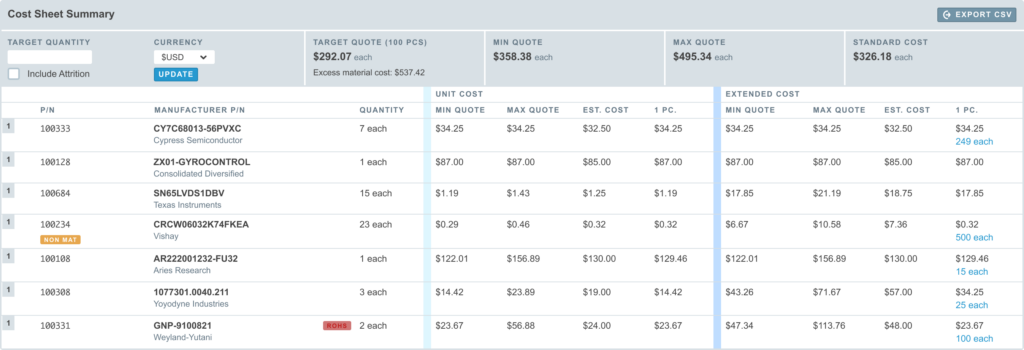

Aligni’s BOM Capabilities Helps You Make Better Decisions and Track Changes

In Aligni, all functionalities work from the same database. That means part pricing and quantities on-hand are available to the engineers creating a product’s bill of materials. Project pricing can be easily calculated from real quotes and purchases as Aligni’s BOMs are directly connected to inventory data. This makes sure the pricing is as accurate and as up to date as possible.

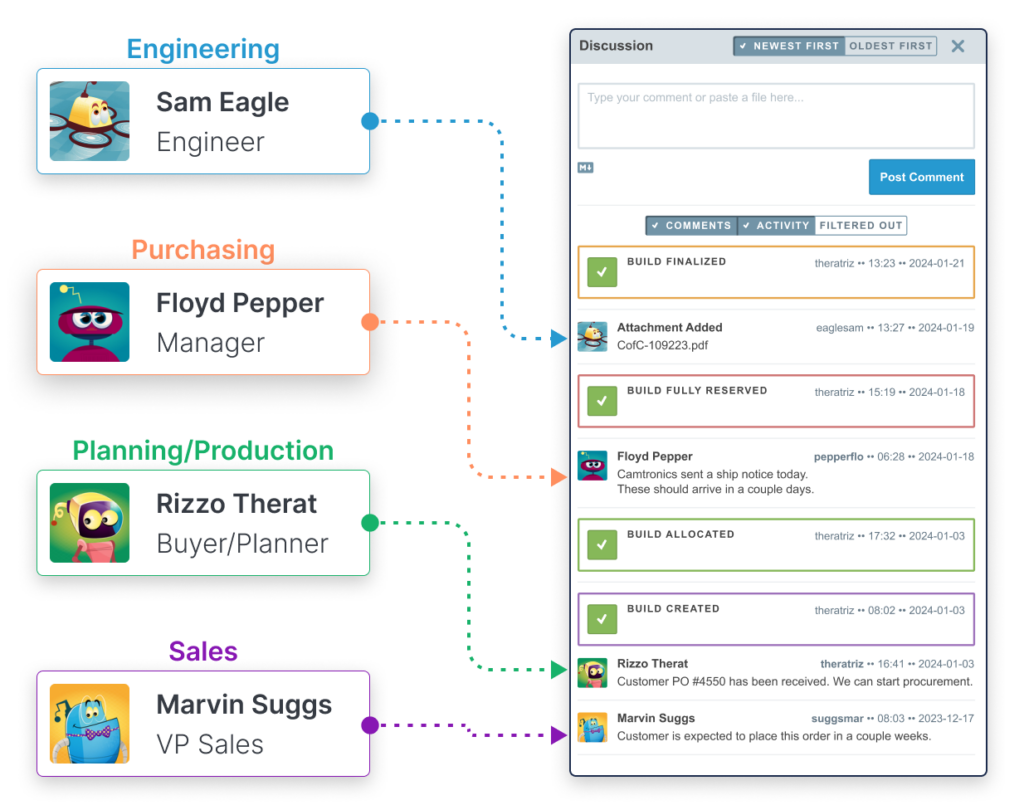

Our revision history tracking functionality captures when the makeup of the BOM changes and more importantly, why the change or updates were deemed necessary. Quantitative revision data is combined with Aligni’s DiscussAnything functionality that captures the conversations and notes leading up to the change. This adds context to the change, reduces double work, and builds a rich database of records lessons learned for later projects.

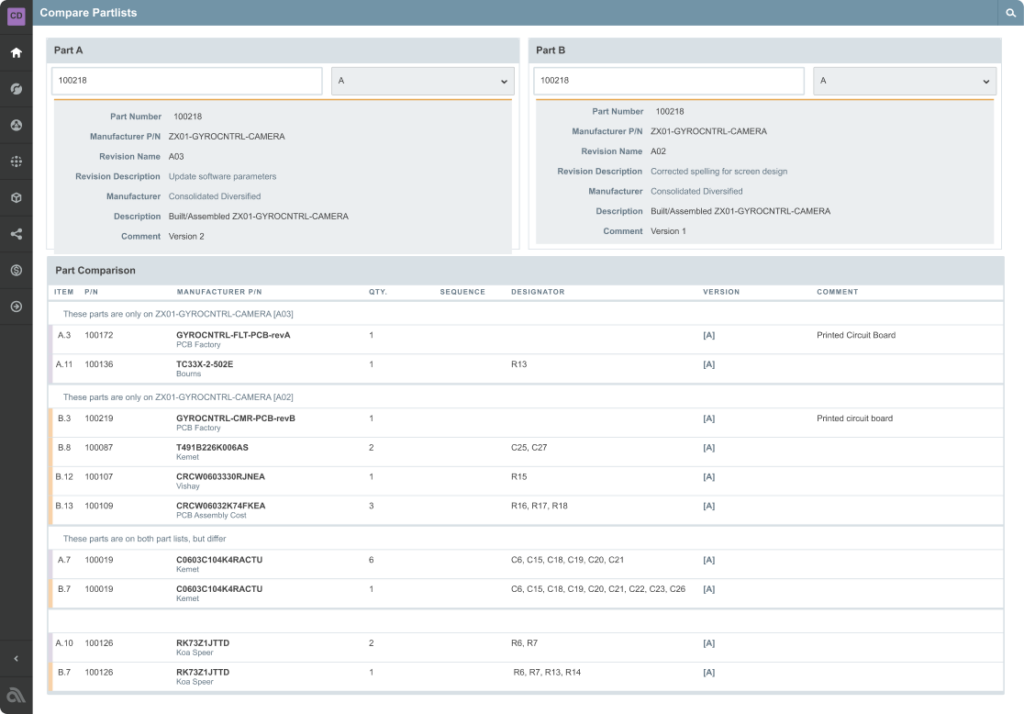

Aligni’s BOM compare functionality empowers organizations to compare BOMs directly in the software. As each BOM in Aligni is built the same way using the same data, differences are easily spotted. This reduces human error and oversight as well as errors from comparing outdated BOMs or phantom BOMs.

Learn more about Aligni’s BOM management capabilities

Aligni Vaults Securely Manage Information Sharing

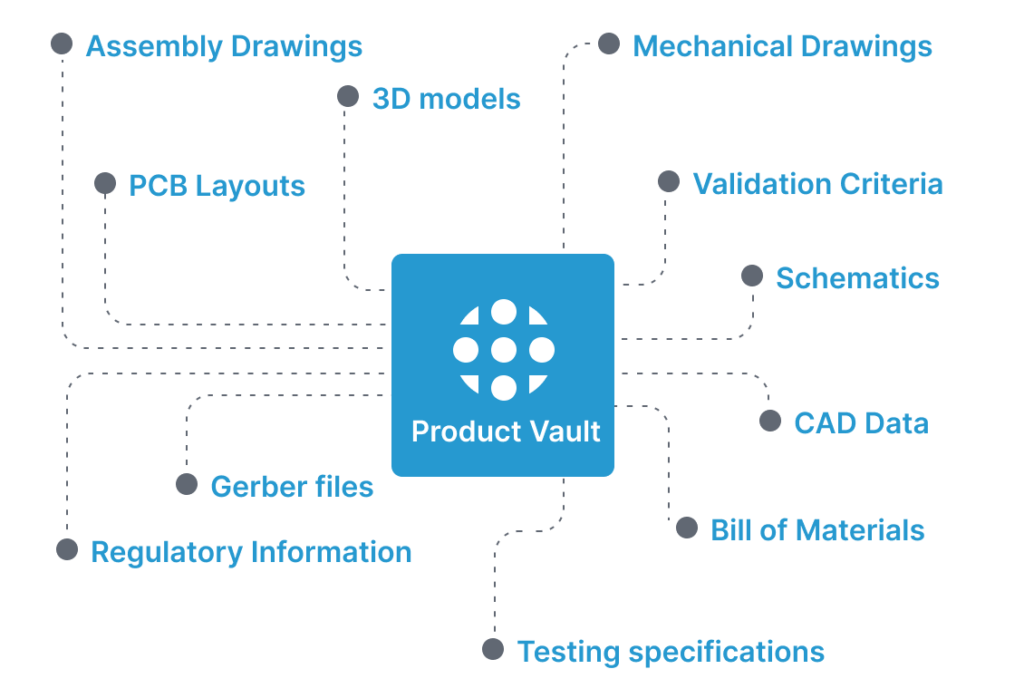

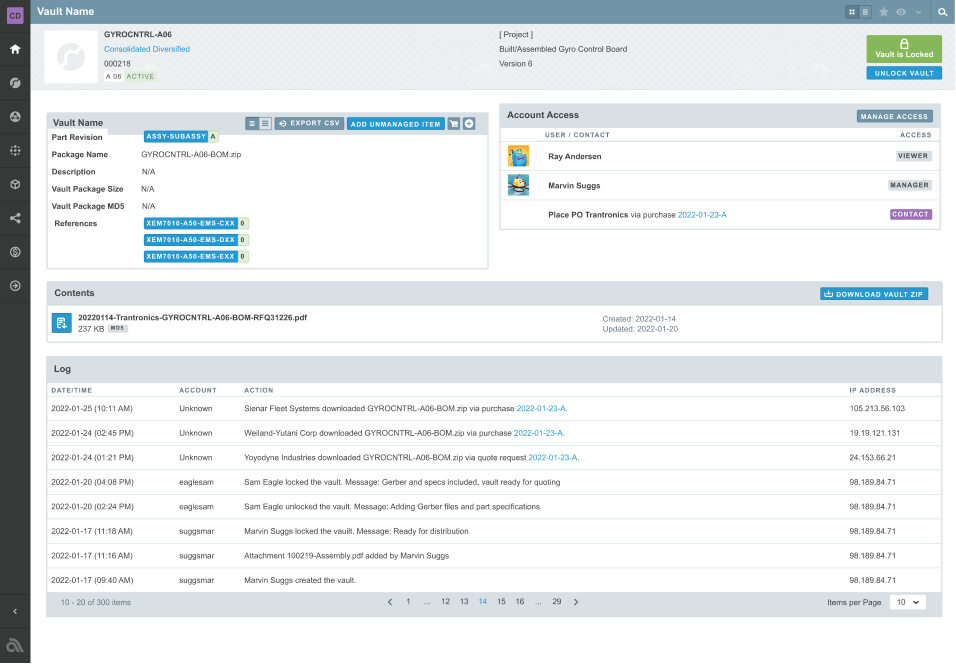

Aligni’s Vaults securely packages BOM information to share with external groups, like customers, suppliers, and contract manufacturers. The vault process pulls information directly from Aligni’ item master database to eliminate translation errors or the use of old information. This makes compiling and distributing product and manufacturing information more efficient and helps guarantee only the most recent material is being shared.

The Vaults go beyond simply providing information. When the information contained within the vault is changed, Aligni provides notifications to the groups granted access. These alerts ensure each member of the vault’s group is alerted to changes as soon as the changes occur. This capability reduces the potential for out-of-date information to be used and keeps external groups current with part and product revisions.

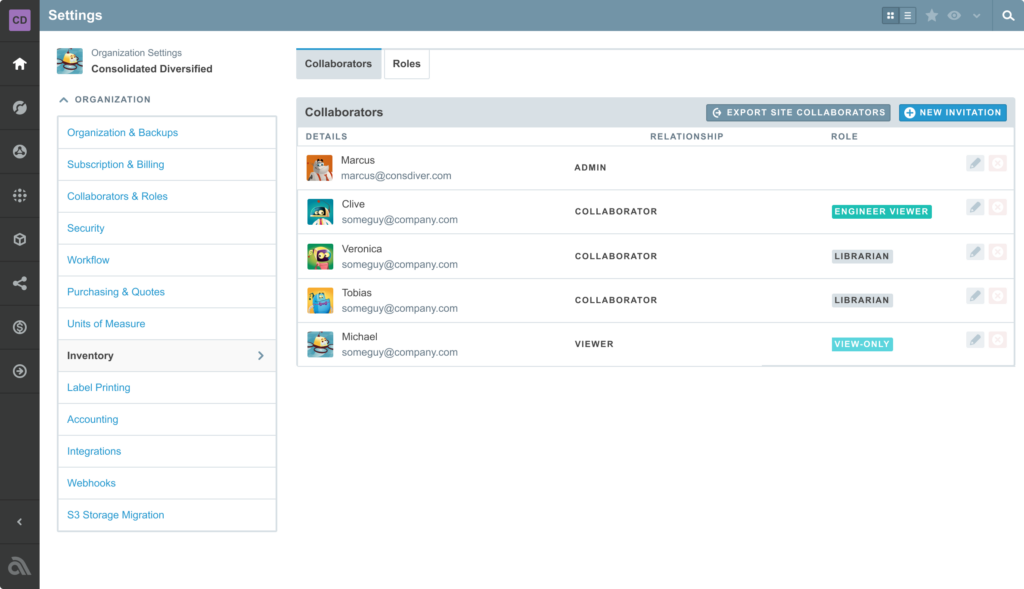

Access control capabilities are built into the Vault information sharing system. Assures the vault owner only the people who need access to the information are able to view the materials. It also provides the ability to remove access to ensure sensitive information is kept as secure as possible – even with outside partners.

Learn more about Aligni’s Vault BOM sharing capabilities

Start your 30-day free trial

Helping You Make Great Things…Better.