Inventory You

Can Count On

Visibility, control, and insight—without the complexity.

Tools for Everyday Logistics

Things change. Aligni gives you the tools to adapt quickly—without compromising accuracy.

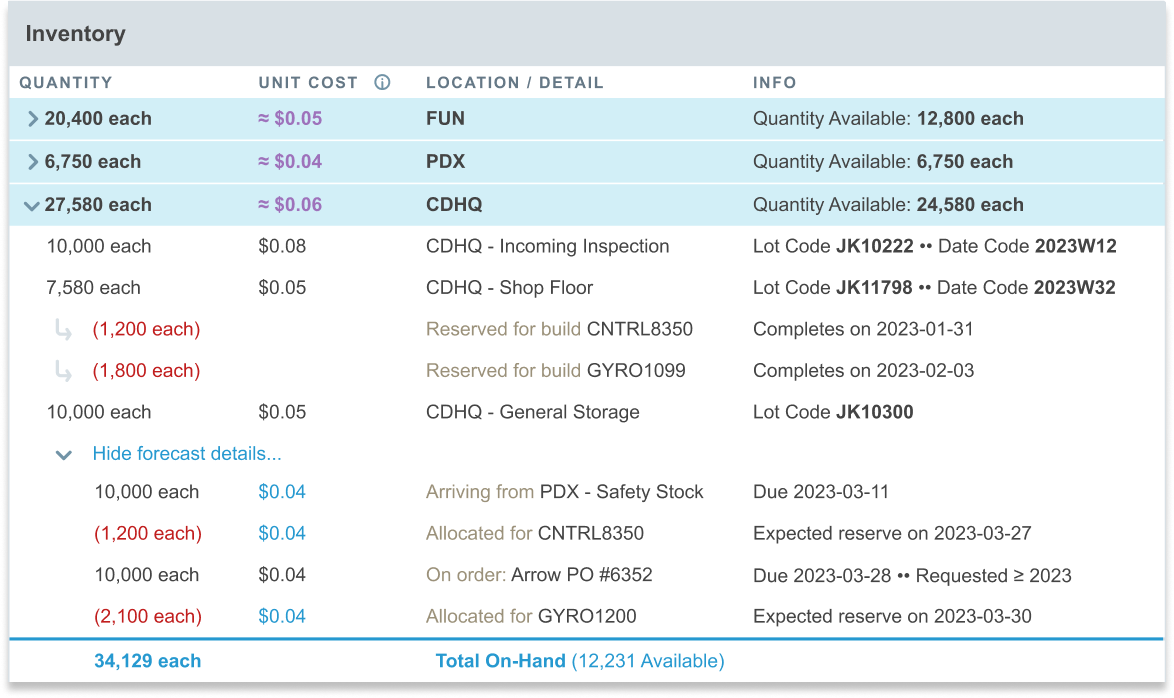

Whether you’re reconciling inventory, correcting shrinkage, or rebalancing stock across locations, Aligni makes it easy to apply updates with confidence. Manual and bulk adjustments are fully logged, and transfers stay tied to the item master for full context and traceability.

- Apply on-the-fly inventory corrections with history logging

- Handle reconciliation, shrinkage, or cycle counts at scale

- Bulk update stock levels across SKUs, sites, and locations

- Transfer inventory between warehouses and zones with audit-ready tracking

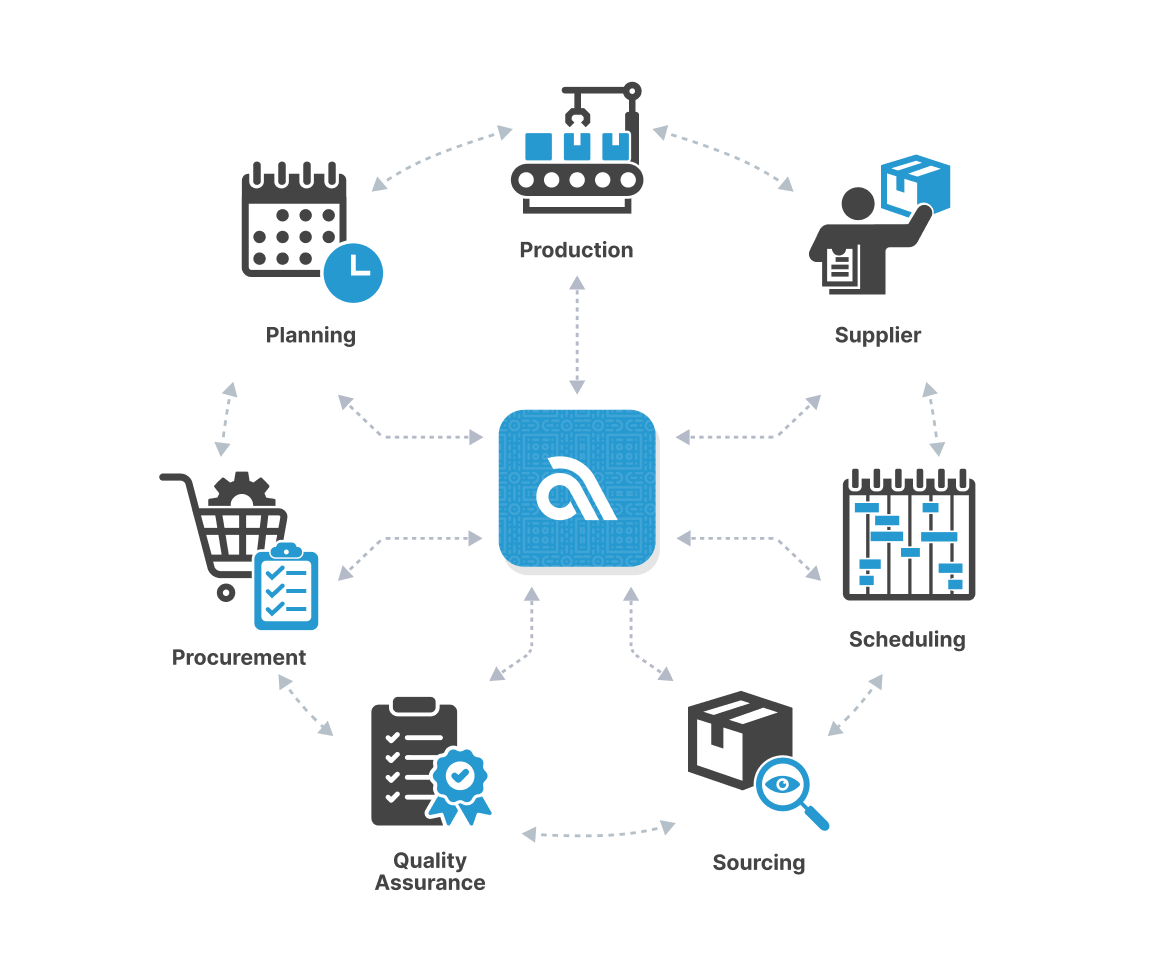

Integrated from Procurement to Production

Inventory doesn’t operate in isolation—and Aligni is built to reflect that. Every inventory decision is connected to your production schedules, procurement plans, and quality checkpoints.

Aligni supports warehouse zones, vendor-managed inventory, and non-nettable locations so you can manage internal workflows, inspections, and external stocking strategies with full visibility and control. Whether you’re kitting builds, staging components, or isolating parts under review, Aligni keeps everything organized and traceable across locations and teams.

From Forecast to Foresight:

What Inventory Outlook Tells You

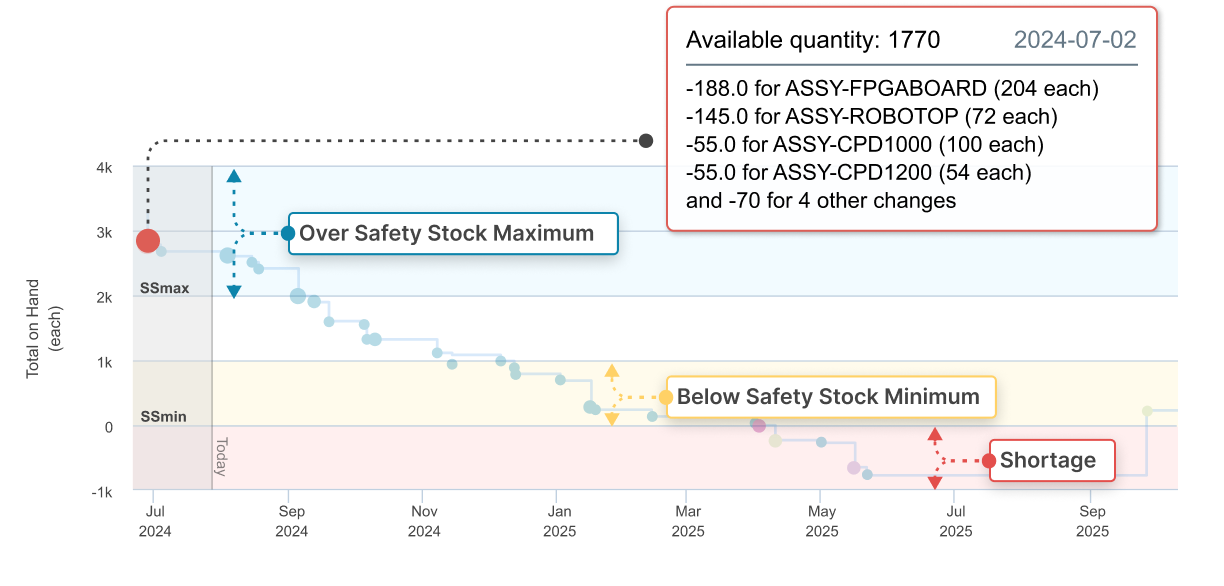

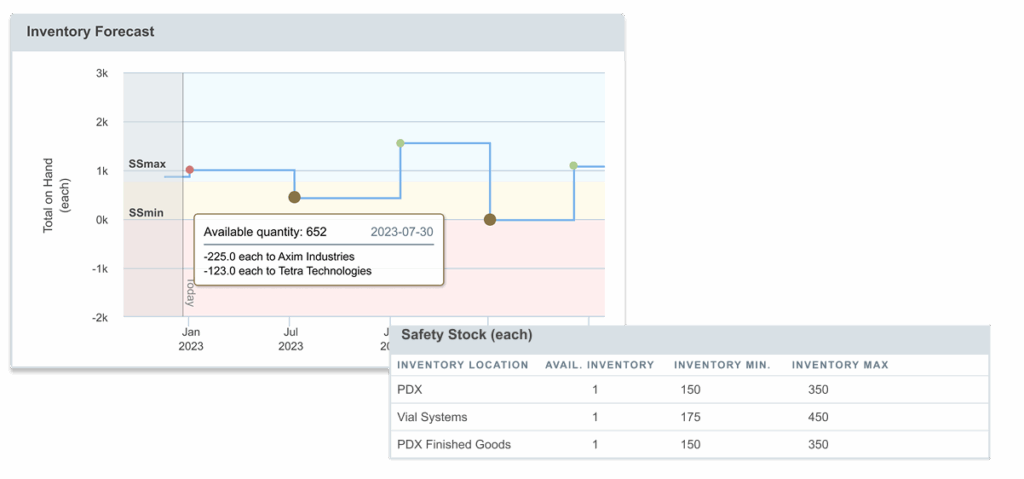

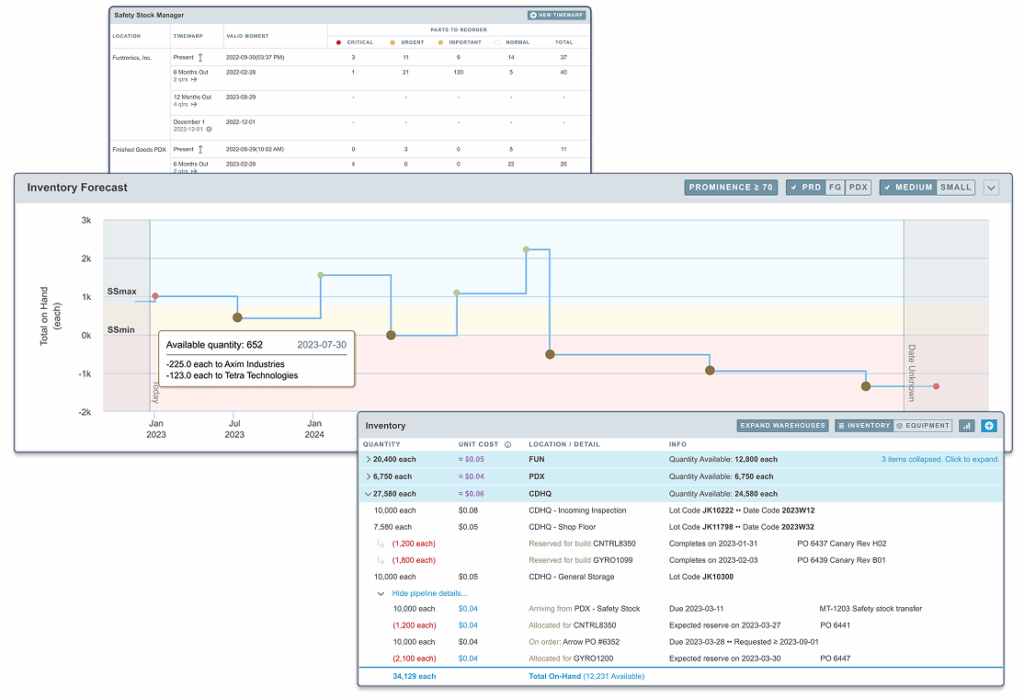

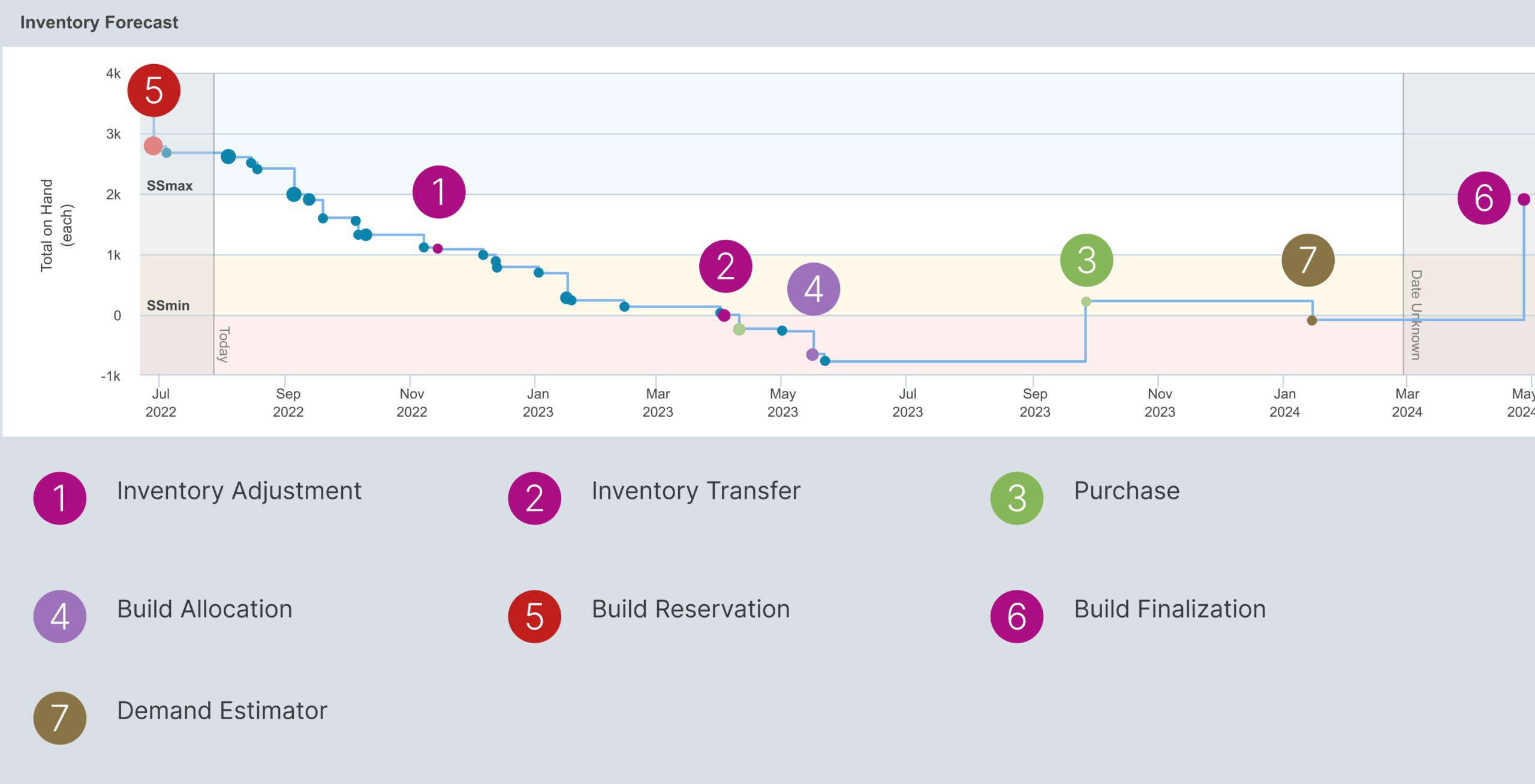

What Drives the Forecast—and How It’s Shown

Influence Factors

Each data point in Aligni’s forecast chart is backed by clear logic and visual context. Every visual marker you see reflects an underlying influence—part movement, supplier delivery, safety stock logic, or build demand.

- Each factor is illustrated by a specific color in the forecast chart

- Every data node is traceable to the quantity or event driving it—demand, inventory, inbound, or shortage

- Hovering over a node reveals a tooltip with deeper context, including timing, quantity, and linked builds or POs

Struggling with Shortages?

Shortages aren’t just surprises. They’re symptoms of planning disconnects, shifting timelines, or unexpected demand. Aligni’s Material Shortage Report helps you get ahead—before production gets held up.

Know exactly what to order, when to order it, and why it matters. Prioritize by urgency, lead time, or build impact. And drive procurement decisions with live demand data—all from a shared, transparent report.

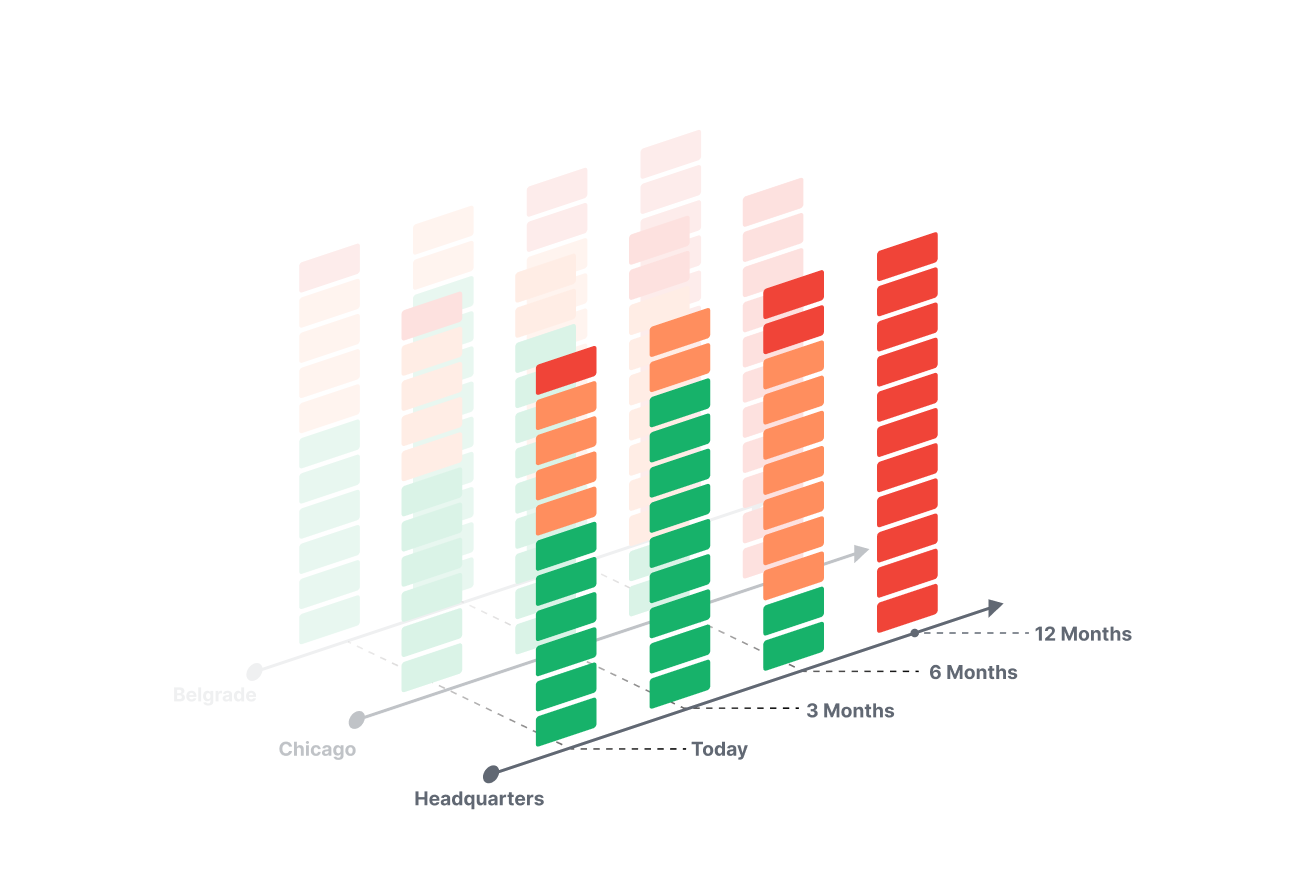

Multi-Warehouse Safety Stock

Too little inventory puts production at risk. Too much ties up cash. Aligni helps you strike the right balance by managing warehouse-specific safety stock levels.

Safety stock levels are driven by your actual usage, demand trends, and supplier lead times—and visualized directly in your inventory forecast. Adjust thresholds as needed and see the impact immediately across reports and discussions. Whether you’re tightening buffers or building in protection, Aligni makes it easy to stay ahead of risk without overcommitting capital.

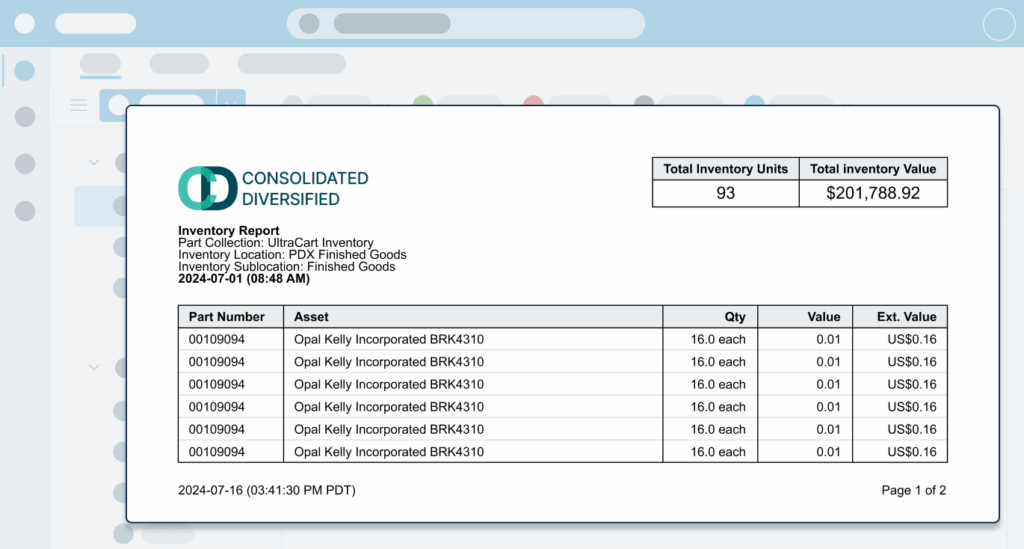

Automate Inventory Reporting

Automated inventory and usage reports keep your team informed without extra effort. From the Reporting page, you can subscribe to reports that arrive right in your inbox—on a schedule you set.

- Choose the format, sorting style, and level of detail you need

- Create location-specific breakdowns, part collections, or company-wide overviews

- Combine historical consumption with forward-looking forecasts to plan smarter

Expedite the Evaluation

Evaluating business software shouldn’t take months. Aligni makes it simple to go from login to live results — no complex setup, no IT support required.

- Test drive a live demo and experience Aligni’s workflows right away. Invite colleagues, load real data, and see how it fits your operations.

- Start a 30-day free trial with free onboarding to get your team moving fast. Importing services are available to help you hit the ground running.