For small to medium-sized manufacturing enterprises, there comes a point where inventory and purchasing management via spreadsheets shifts from being beneficial to cumbersome. Astute supply chain managers recognize this as the cue to transition to specialized software for their processes. In such scenarios, they usually opt for Material Requirements Planning (MRP) software. Software like Aligni MRP becomes their go-to solution for handling aspects such as part demand, inventory management, and procurement.

MRP software helps businesses manage their manufacturing processes by generating accurate material requirements, tracking inventory levels, and facilitating production planning. It uses data such as bills of materials, inventory records, and production schedules to optimize material availability, minimize inventory costs, and ensure smooth production operations. Cloud-based MRP software also provides manufacturers with the ability to increase interdepartmental collaboration. This is done by storing product information in a commonly accessible item master database instead of in separate files.

Let’s delve into how MRP systems, such as Aligni, can provide more advanced features for supporting supply chain processes compared to traditional spreadsheet-based systems.

Demand Forecasting

MRP systems sometimes integrate with sales and demand forecasting systems to gather data on customer orders and forecasted demand. Other MRP systems like Aligni can help perform demand forecasting and demand estimation itself. This information serves as the basis for generating material requirements and making sure the right amount of materials are on-hand.

Bill of Materials (BOM) management

A bill of materials is a hierarchical list that outlines the components, parts, and quantities required to manufacture a product. MRP systems store and manage BOM data and make it available to the relevant departments within the firm. This allows for accurate calculation of material needs for production builds.

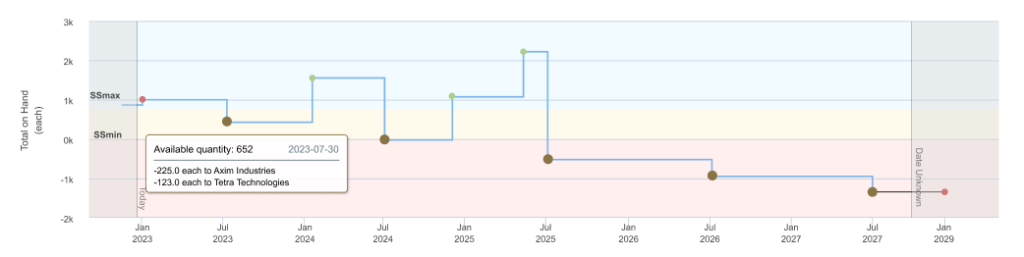

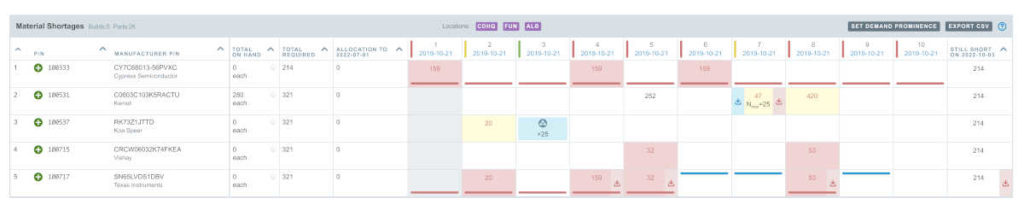

Inventory Management

MRP systems maintain an item master database that tracks the availability and levels of raw materials, components, and finished goods. By continuously monitoring inventory levels and comparing them against the demand forecast, the system determines the required quantities of materials to maintain optimal stock levels.

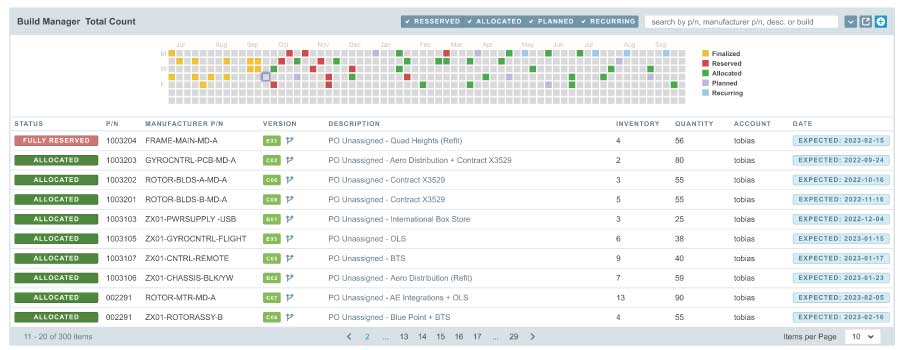

Production Scheduling

MRP systems consider the availability of materials, production capacities, and lead times to create production schedules. This helps in optimizing production processes and ensuring that the right materials are available at the right time for manufacturing.

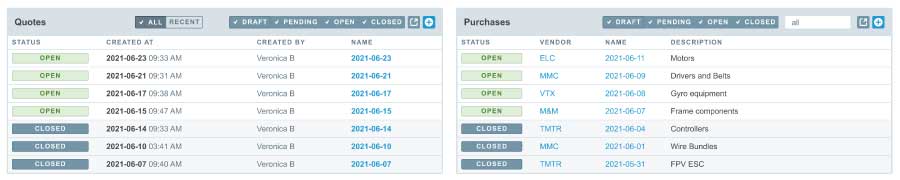

Purchasing Process Tracking and Control

MRP systems provide real-time visibility into the status of orders, inventory levels, and production progress. This enables supply chain managers to monitor the flow of materials, identify bottlenecks or delays, and take corrective actions to maintain efficient operations.

Reporting and Analysis

MRP systems generate reports and analytics on various aspects of the supply chain, such as inventory turnover, lead times, supplier performance, and production efficiency. These insights help in identifying areas for improvement, optimizing processes, and making informed decisions.

These are just a few examples of the ways transitioning to MRP software from spreadsheets can help a business improve their efficiency. By leveraging an MRP system, organizations can streamline their supply chain operations, reduce inventory costs, minimize stockouts, improve order fulfillment, and enhance overall supply chain efficiency.

Tired of managing spreadsheets and tracking down inventory and purchasing information? It’s time to sign up online for Aligni MRP!

Start your 30-day free trial

Helping You Make Great Things…Better.