Aligni Provides the Tools to Manage Your Inventory Needs

Consolidate your inventory and production management in one application with Aligni and ensure seamless operations with more efficient part and material utilization. Our tools manage component demand and inventory forecasts against upcoming production requirements.

Manage Your Day-to-Day Inventory and Production Needs from One Application (Ver. A)

The Central Hub for Knowing What’s Happening Now

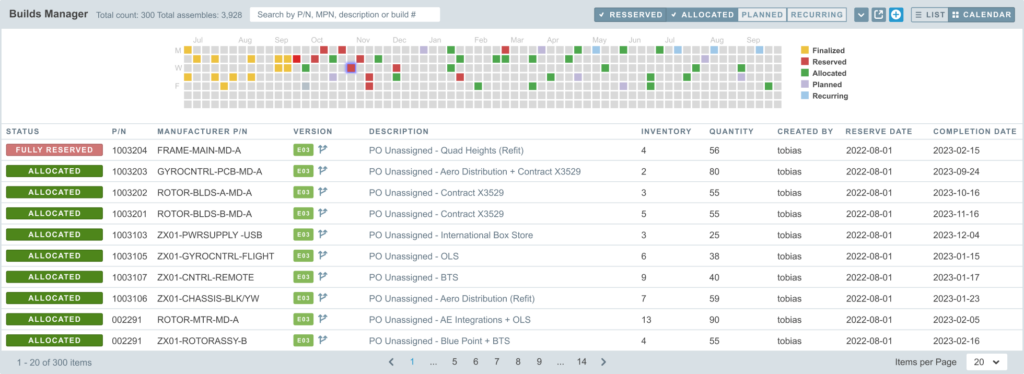

Complexity doesn’t just happen in the future. Overseeing the needs of today’s builds can be just as challenging as managing over the long term. Aligni is designed to reduce inventory management complexity with tools that help buyers and managers quickly identify, assess, and act on issues that may arise.

Introducing the Aligni MSR

Aligni’s Material Shortage Report (MSR) helps break down the individual, short term part needs of each build. The report’s color coding and icons quickly explain current conditions and where attention needs to be placed first. Aligni’s advanced MSR is updated in real-time and efficiently operates with scores or even hundreds of builds on the production schedule.

Get the Details at a Glance

Aligni’s material shortage report helps organizations understand pending resupply orders. The MSR can sort these orders by lead time, need-by date, or a variety of other filtering approaches (e.g. part type, assemblies, manufacturer). The Aligni MSR also provides order lead time indicators on the same display.

Learn more about Aligni’s Material Shortage Report

Manage Your Day-to-Day Inventory and Production Needs from One Application (Ver. B)

The Central Hub for Knowing What’s Happening Now

Complexity doesn’t just happen in the future. Overseeing the needs of today’s builds can be just as challenging as managing over the long term. Aligni is designed to reduce inventory management complexity with tools that help buyers and managers quickly identify, assess, and act on issues that may arise.

Introducing the Aligni MSR

Manage Inventory from a Central location

Get the Details at a Glance

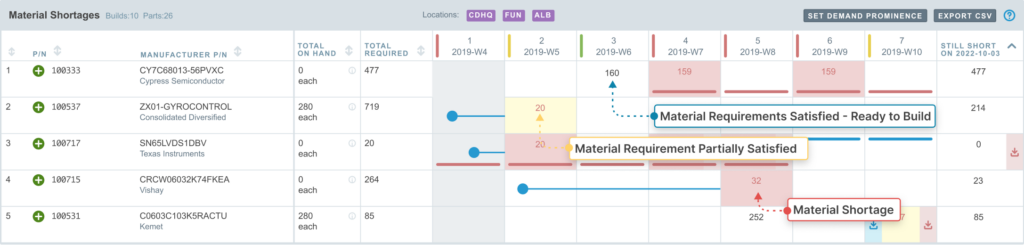

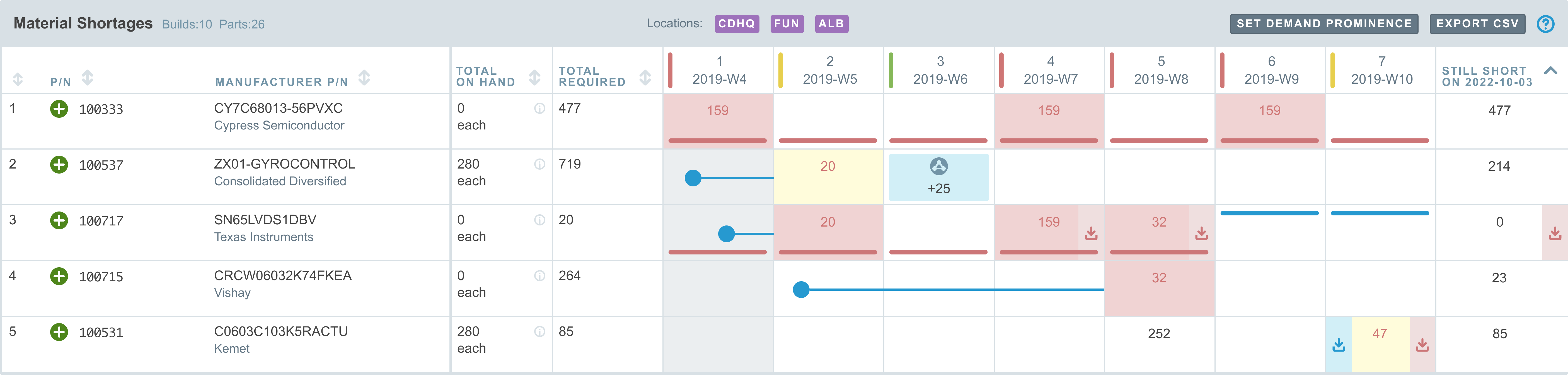

Aligni’s Material Shortage Report (MSR) helps break down the individual, short term part needs of each build. The report’s color coding and icons quickly explain current conditions.

The advanced MSR is updated in real-time as production and inventory situations change. The report efficiently operates with scores or even hundreds of builds on the production schedule.

Aligni’s MSR helps organizations understand pending resupply orders. The MSR can sort orders by lead time, need-by date, and more. It also provides order lead time indicators on the same display.

Learn more about the Aligni MSR

Dig deeper into builds shown on the MSR

Learn more about the information on the MSR

Tools to Help You Know What’s Going On Now

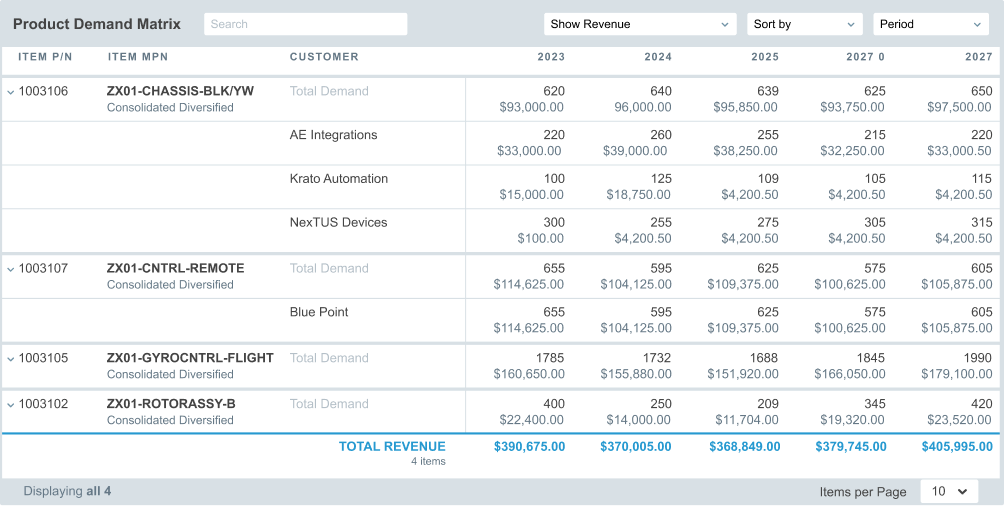

Managing inventory and production effectively starts with collecting all available information and presenting it in a way that presents a clear picture of what’s needed in the future. That’s what Aligni does with its Demand Matrix and Inventory Forecast tools.

Combine All Product Demand into One Chart

Starting with customer demand, Aligni compiles the quantities needed for every sales order into its Product Demand Matrix screen. It combines all anticipated product demand into one screen for easier understanding of what’s needed for the entire organization. The revenue, gross profit, and customer breakdowns provided in the Product Demand Matrix can be useful for financial forecasts and investor relations.

Learn more about the Product Demand Matrix

Easily Break Down Product Demand into Part Demand

Aligni’s Component Demand Matrix screen provides a similar collated view for the parts and materials that go into the orders listed in Product Demand Matrix. This breakdown provides specific strategic benefits to organizations. Sharing these component forecasts with vendors can help lead to better long-term pricing contracts by combining individual build needs into larger group orders further out in time. Component Demand Matrix also helps understand part lifecycle awareness to highlight high use parts instead of specifying sunsetting parts.

Learn more about the Component Demand Matrix

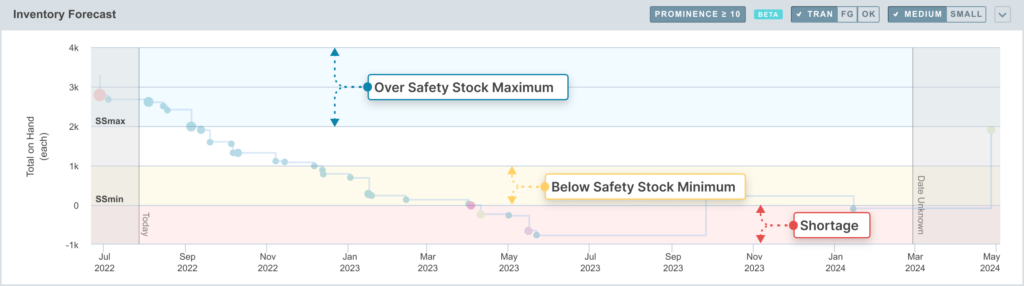

Forecast Future Part Needs

The Inventory Forecast tool helps businesses understand near term part and material demands. This helps companies anticipate when parts and materials will dip into safety stock levels before they do and plan accordingly. The tool’s graphical format quickly explains how production demand will affect inventory levels and safety stock thresholds. Aligni also displays drop dead order dates for parts on the same screen. This helps companies better plan and order materials to make sure upcoming builds never stock out.

Learn more about Inventory Forecast tools

Tools to Help Get Your Ready for Future Needs

Aligni’s demand planning tools help organizations develop long term estimations of part and material needs. Having the ability to look further into the future helps purchasing teams become more proactive in managing inventory requirements and provides the knowledge to negotiate better terms from larger and more consistent ordering.

Introducing Flow Demand

Aligni’s Flow Demand tool projects future needs by using sales expectations and current run rates. Flow demand offers lifecycle estimation over user defined periods. These periods can be configured to more accurately forecast ramp-up and growth stages, sustained production periods, and phase-out. Flow Demand provides a more nuanced, real-world modeling of future product demand than straight line estimation. Being able to model more closely real-world inventory needs helps production and purchasing teams balance build requirements over longer time periods to find more efficiencies.

Learn more about Aligni’s Flow Demand capabilities

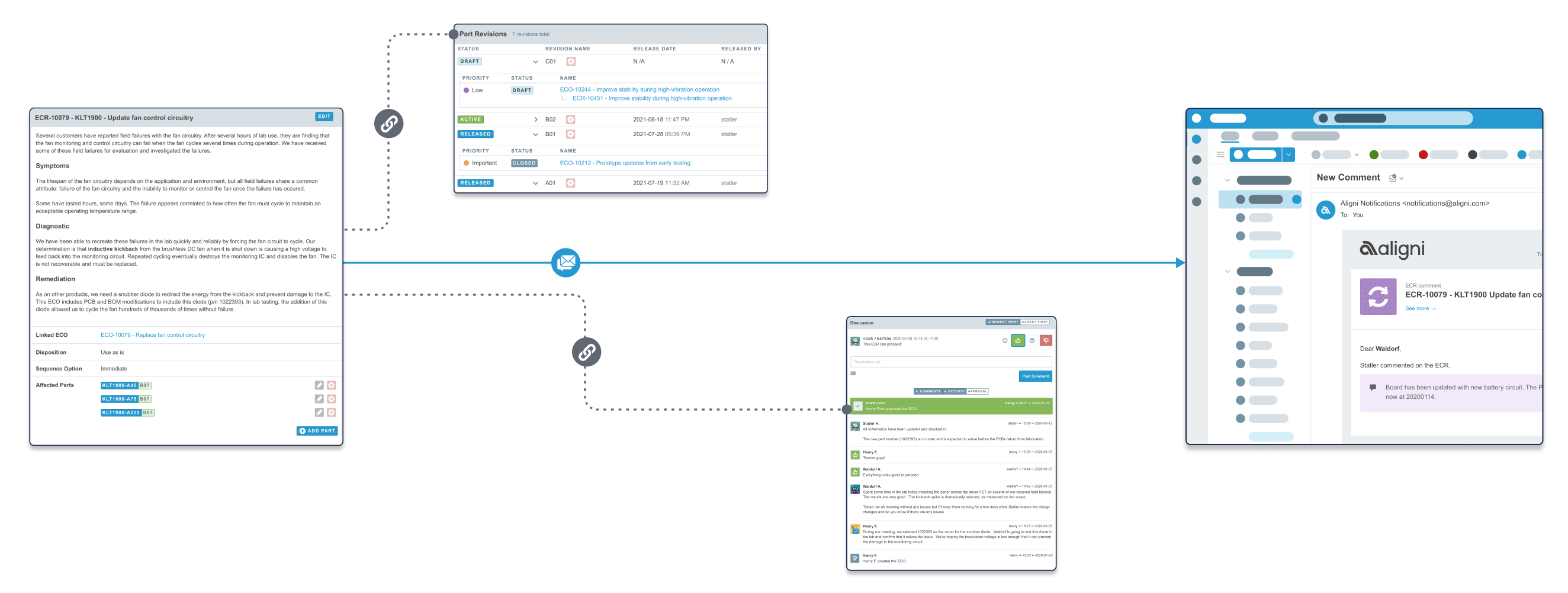

Inherently Collaborative System Connecting your Organization’s Departments

Reduce the complexity without the pain.

Start your 30-day free trial

Helping You Make Great Things…Better.