PLM

Engineering Change Management with Aligni PLM

Aligni takes ECM oversight further by facilitating collaboration among cross-functional teams, speeds up approval workflows, and provides a transparent audit trail, improving accountability and regulatory compliance.

Moreover, Aligni enhances product quality by enabling rigorous evaluation of proposed changes, fostering innovation through knowledge sharing, and supporting long-term tracking of change effects for data-driven decision-making. In sum, operating an Engineering Change Management (ECM) system within Aligni PLM significantly enhances the overall efficiency, quality, and competitiveness of a company’s product development processes.

Integrating ECM into Product Development

Aligni PLM facilitates the Engineering Change Management (ECM) process at several key points throughout the product development and lifecycle management phases. Here are the primary areas where Aligni manages the engineering change management process for manufacturers:

Initiating the Change Request Process

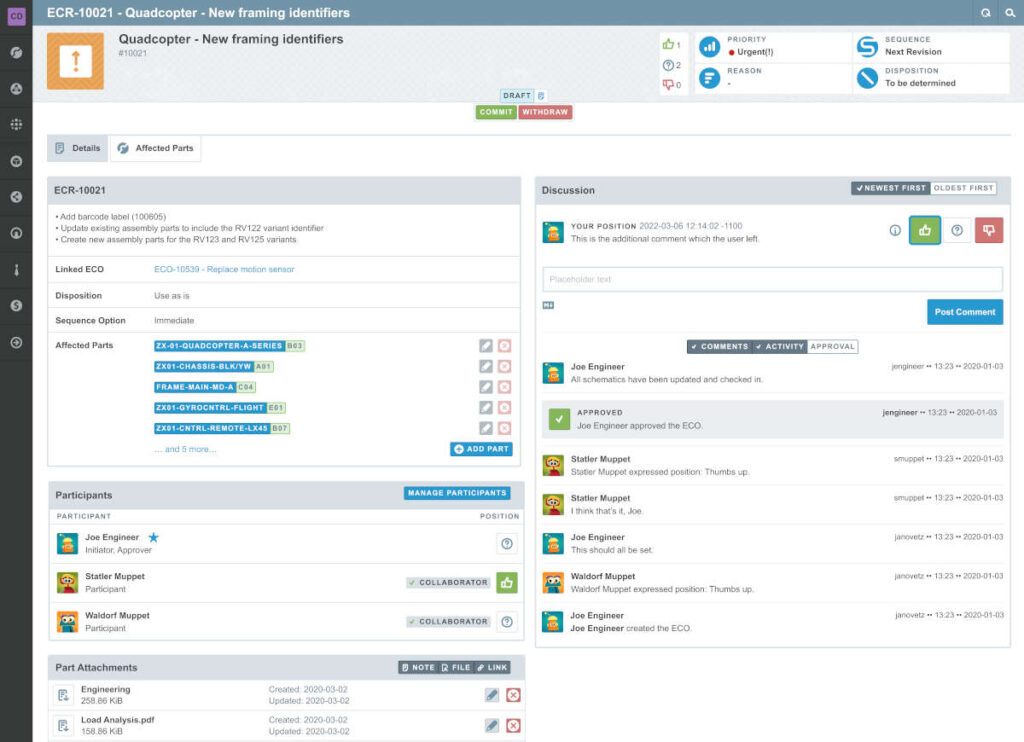

The ECM process begins with the identification of a need for a change in a product’s design, specifications, or documentation through the publishing of an Engineering Change Request (ECR). This change request is initiated within Aligni PLM.

Managing Change Request Documentation

The PLM system is used to create and document the change request, including details about the proposed change, its rationale, and its potential impact on the product. All relevant data, such as CAD models, drawings, BOMs, and associated documents, may be linked and managed within the PLM system. The discussion and decision-making process among collaborators also occurs within the PLM system for improved documentation.

Overseeing the Approval Workflow

Aligni PLM can manage the ECM workflow from the initial change request to the issuance Engineering Change Order (ECO). It tracks the progress of approvals and ensures the appropriate stakeholders are involved in the decision-making process. Notifications and alerts can be triggered within the Aligni to keep relevant parties informed and what needs to happen next in the process.

A Partner in Change Implementation

Since Aligni also manages a company’s bills of materials (BOMs), part and material information, and supplier interactions and data, making the required changes is far more streamlined. Within the PLM system these processes are all interconnected with the ECM process. A change in one area reflects through every other connected aspect – without the need for emailing colleagues of changes or calling update meetings. Aligni also facilitates communication with suppliers and external partners affected by the change.

Managing Change Documentation and History

Aligni PLM maintains version control for product-related data, ensuring that the latest approved versions are accessible to authorized users. This prevents confusion and errors caused by using outdated information. It ensures that all changes are accurately reflected in the product data and serves as the single source of truth for the product being developed.

Throughout the ECM process, Aligni PLM maintains a comprehensive audit trail of all actions and decisions related to the change, as well as discussions and comments made within the system. This audit trail is valuable for tracking the history of changes, ensuring transparency, and facilitating regulatory compliance.

After changes are implemented, Aligni can continue to provide value to the organization. The PLM can be used to track and manage the long-term effects of those changes on the product’s performance, cost, and quality. This can lead to valuable insights for future improvements and iterations.

Explore what Aligni Can Do for Your Organization

Bringing It Together: Integrated PLM and ECM

In sum, the value in using Aligni PLM to manage engineering change stems from its properly designed and executed ECM system that delivers oversight and collaboration. It also comes from how the ECM process is integrated with the product lifecycle management aspects of the software. Combining these two provides invaluable benefits to product development and manufacturing operations that help save time, reduce errors, and increase collaboration.

If you’re looking for a PLM system that is tightly integrated with the ECM process, Aligni PLM is your best choice. It’s built to provide a centralized platform for initiating, documenting, evaluating, and implementing engineering changes while ensuring data accuracy, version control, and compliance throughout the product lifecycle. Sign up for Aligni PLM today!

Start your 30-day free trial

Join over 4,000 teams that are manging their manufacturing with Aligni.