-

Aligni Recommends: Strengthening Supply Chain Strategies Article by Forbes Magazine

Forbes has recently put out an article that details how to make your supply chain more resilient and dependable. The article goes into several aspects and processes to make sure the right vendors are being…

-

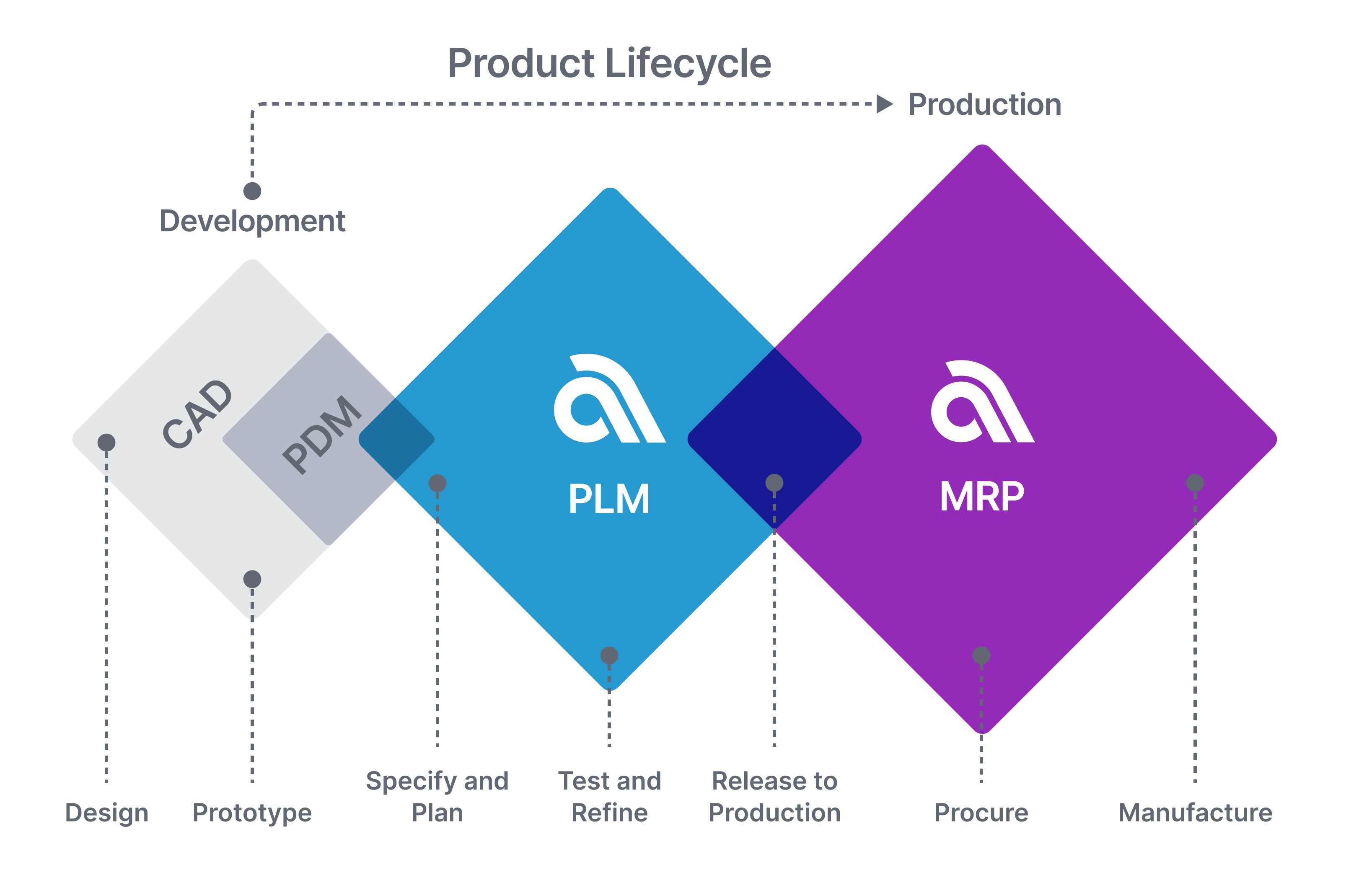

How to Know When You Need a PLM System

Product development and management processes have a lot of moving parts to oversee and there’s a lot riding on things going well. Many times, smaller companies and hobbyists often try to manage their BOMs and…

-

Why Supply Chain Managers Use MRP

For small to medium-sized manufacturing enterprises, there comes a point where inventory and purchasing management via spreadsheets shifts from being beneficial to cumbersome. Astute supply chain managers recognize this as the cue to transition to…

-

Your Homegrown, Spreadsheet-Based MRP System Is Costing You Productivity

Relying on spreadsheets to manage inventory and production needs seems like a quick and easy solution in the beginning. Afterall, spreadsheets are low-cost, reliable commodity tools that are broadly familiar to nearly anyone working with…

-

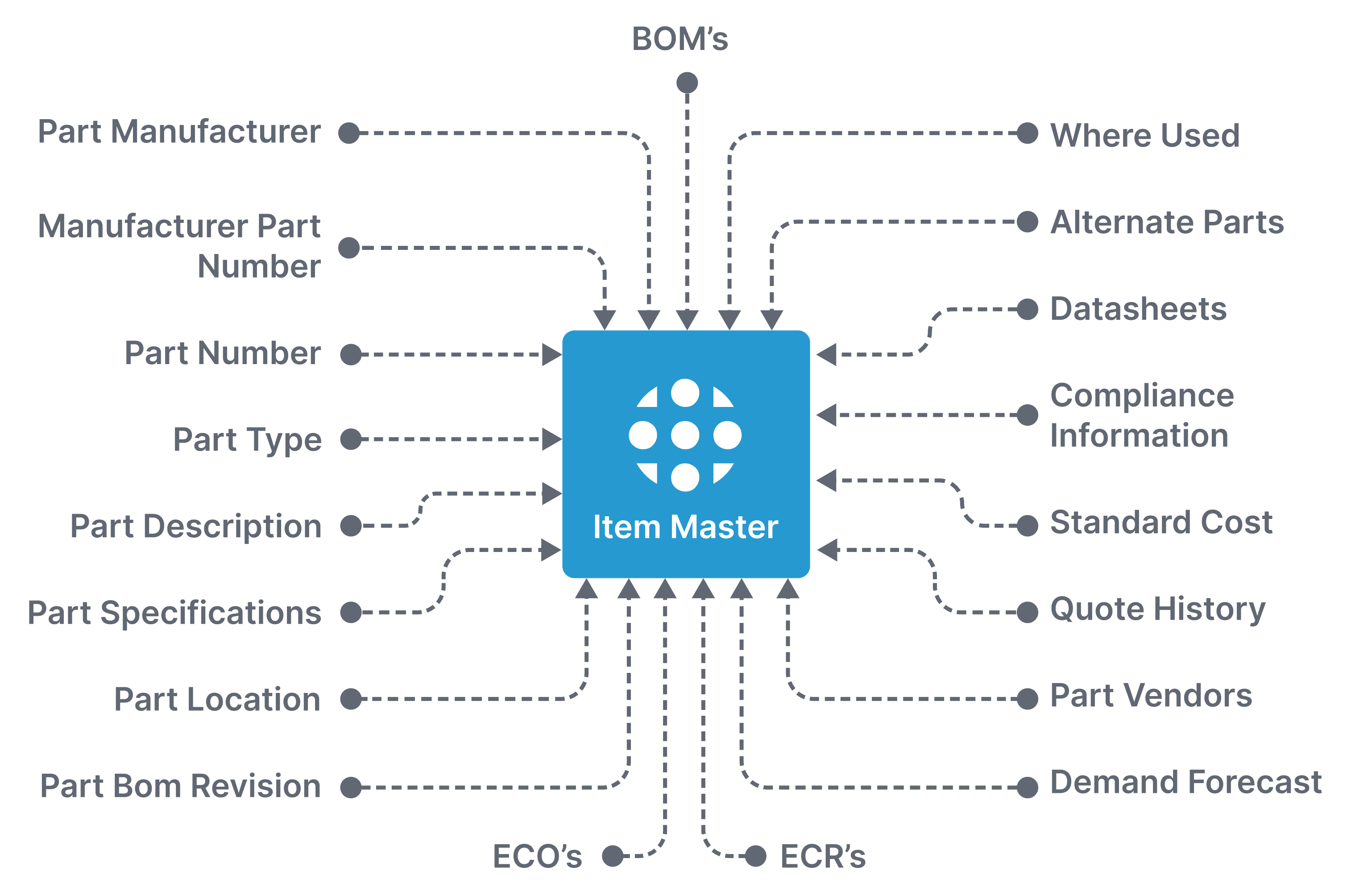

Work Smarter with Item Master Equipped PLM and MRP Systems

In the day-to-day and over the long term, a manufacturing company manages a large amount of data and communication regarding the parts and materials it uses to make its products. Using a centrally-located database system…

-

Product Engineering Needs PLM

Achieve Better Organization, Collaboration, and Efficiency in Product Development Using Product Lifecycle Management (PLM) Systems for Component Information Management Product Lifecycle Management is more than just a quality process. It is an approach to product…

-

Why Use MRP Software over Spreadsheets

It is still common practice for many firms to manage their inventory and supply chain operations with some form of spreadsheet. Often, these spreadsheets are home-grown and built from on-the-job lessons learned by managers and…