-

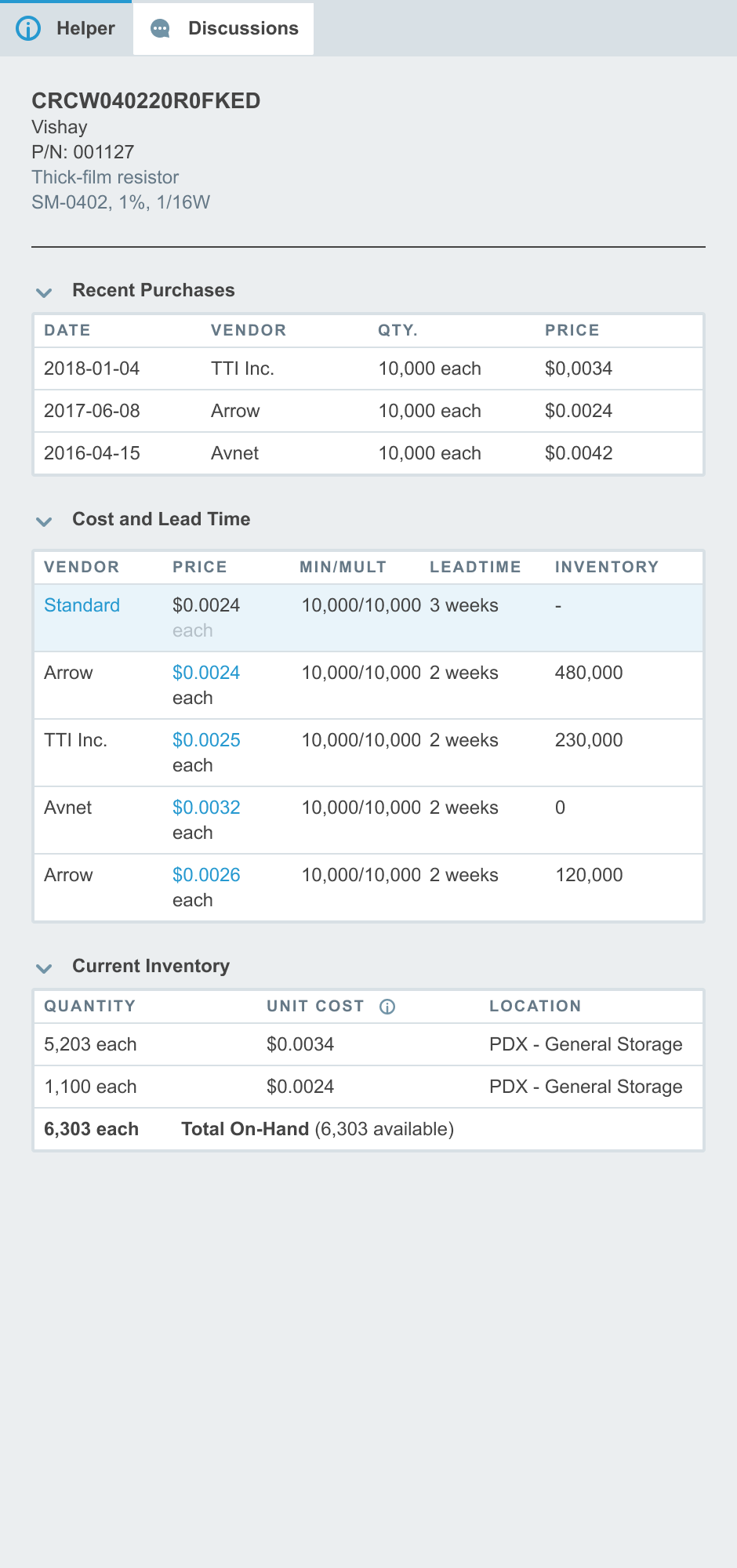

Why Saving Your Purchasing Data Can Make You a Better Buyer

Past performance is key to getting the future right. Purchasing history is a buyer’s best resource. Purchasing is a process that finds its efficiency in knowing as much about what’s going on as possible. That…

-

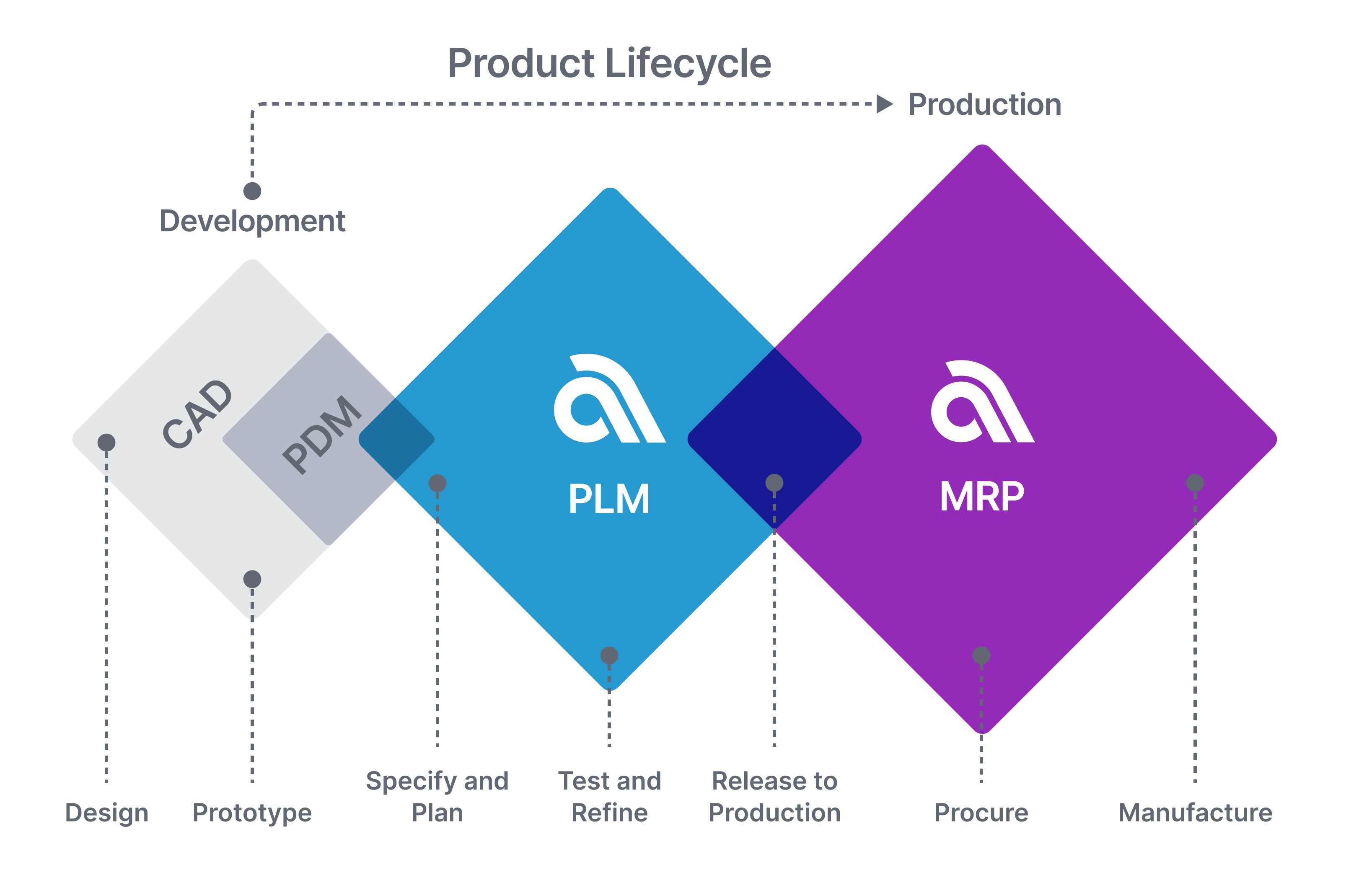

Aligni Recommends: Benefits of Using Product Lifecycle to Manage BOMs

The International Society of Automation has put together a rather extensive article on how modern Product Lifecycle Management (PLM) systems manage Bills of Materials (BOMs) and why that’s been effective for so many manufacturing organizations.…

-

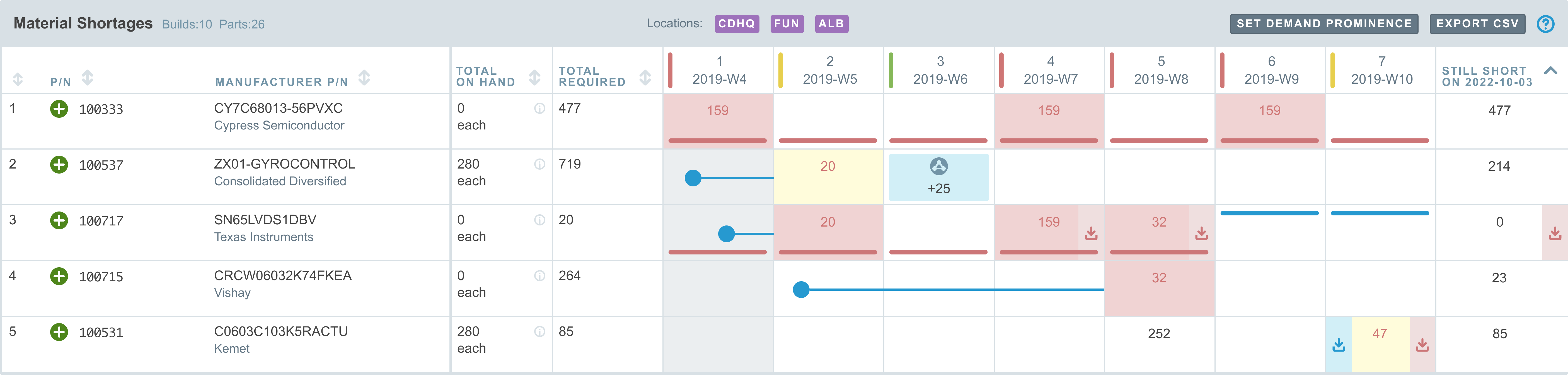

Master Part Ordering with New Aligni Lead Time Tools

Managing inventory requires overseeing a variety of aspects. One of the most important is scheduling orders to make sure the parts are there before production needs them. That means understanding how long it takes for…

-

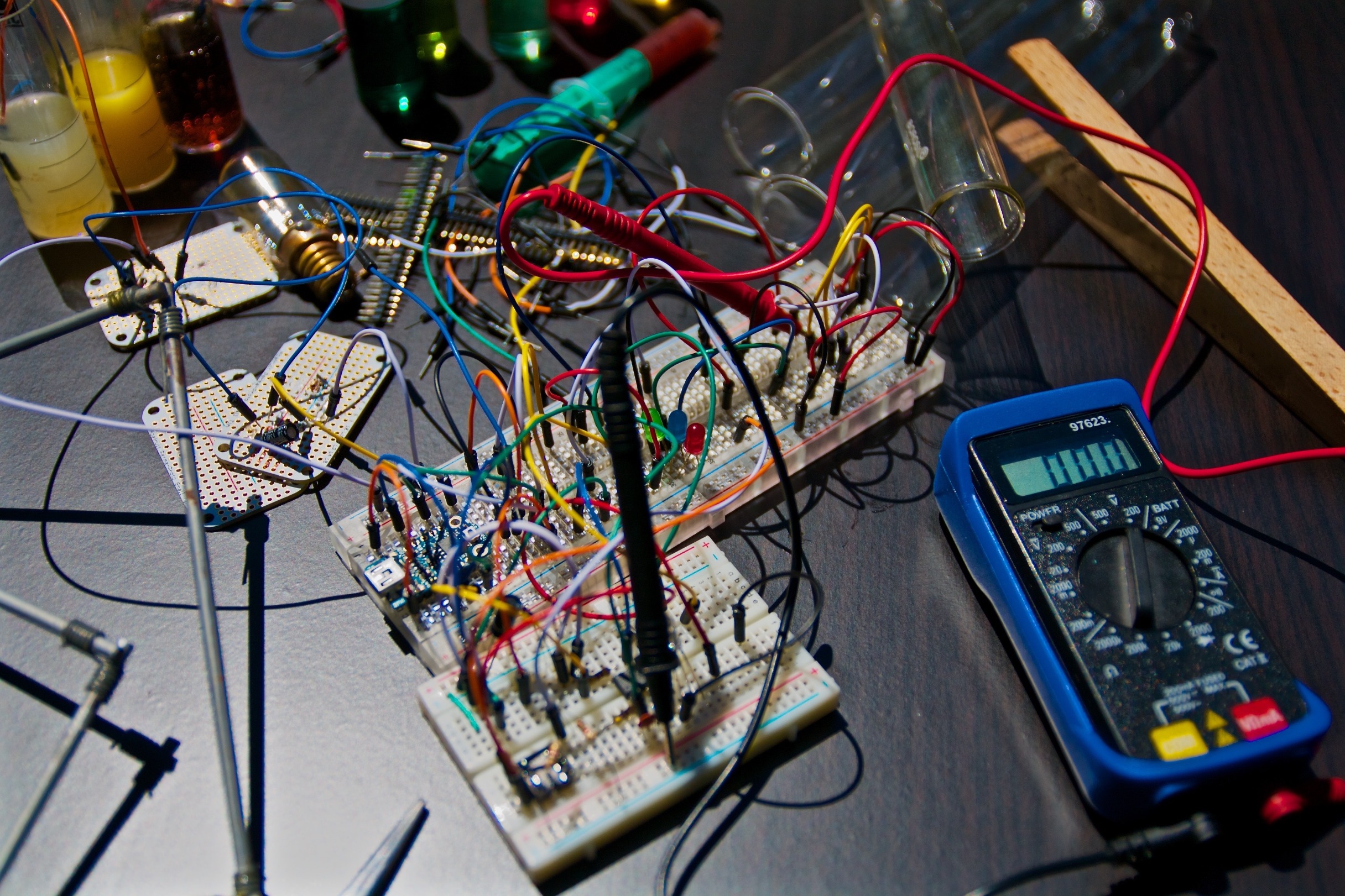

Aligni Recommends: 5 Steps for Optimizing Your Electronics Manufacturing Production Planning

Getting more out of your manufacturing process starts at the beginning with good planning. EMSNow put out a great article on how to approach streamlining your production planning operations to unlock greater efficiency and throughput.…

-

Fall 2023 Update

It has been a productive summer at Aligni. As Halloween approaches and the leaves fall, we wanted to share with you some of our recent updates and maybe a bit of a tease about what’s…

-

Can You Tell When an Engineering Change Management System Is Needed?

Larger manufacturing organizations employ a number of advanced processes to manage production operations. The processes help guarantee efficiency, quality, and on-time delivery. For smaller firms, these systems tend to be too burdensome to make sense…

-

Aligni Recommends: ERP Implementation: 5 Ways to Handle Change

For small and medium sized businesses, most Enterprise Resource Planning (ERP) systems are just too expansive for their purposes, but that doesn’t mean companies cannot learn best practices on their path to adopting more right-sized…