PLM

Bill of Materials Management with Aligni

Sifting through a large bill of material or lists of individual sub-assembly files can be a time consuming and confusing process. Aligni provides the ability to take the complexity out of complicated parts lists through highly refined part management abilities and streamlined interfaces.

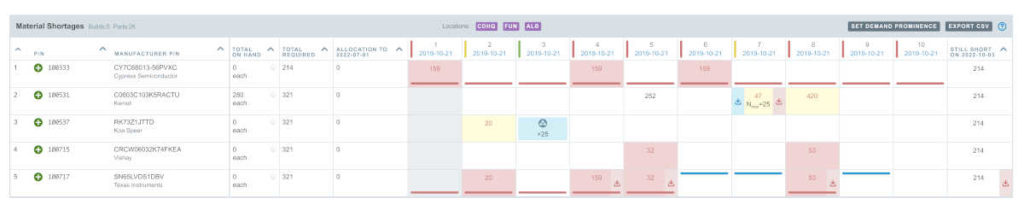

Aside from providing an intuitive system to update and modify materials lists, Aligni’s interfaces convert part data on complicated builds into easy to understand information. The Part List view breaks BOMs down in a hierarchical format that provides an intuitive display of nested parts lists. The software can also display BOMs into flattened assembly lists in its Kit List. This format allows companies to see all parts used, regardless of nesting.

While getting to your part data is paramount, that’s not all Aligni can do.

Proactively Manage Material Requirements

Estimate product costs accurately and confidently across the entire build hierarchy based on standard costs or supplier quotes at multiple price breaks. Aligni is much more than just BOM management – it offers extra functionality that lets users analyze the makeup of builds with its charting and computation capabilities. Discover what makes up a build by part quantity or by part cost with a click of a button. Aligni can sum part quantities and costs across the entire build – including every sub assembly in the build – for accurate cost estimation.

Need to perform calculations on the makeup of a BOM by certain product features like part mass, voltage or capacitance? Aligni can do that. The software can scrutinize the entire assembly to find the parts that can handle the least amount of voltage in the build, quantity of electrolytic capacitors have been specified or other parameters need to be confirmed before production begins.

Explore what Aligni can do for your organization

Share Build Information Easily

Aligni offers part list and part importing features. Using the widely adopted CSV format, Aligni can update current information or input new information into its system from customers or vendors without having to manually key in information.

Whether ordering parts or outsourcing processes, Aligni also provides an easy method to export lists to vendors and contractors. By exporting data directly from the system, companies can greatly reduce miscommunication and lost details.

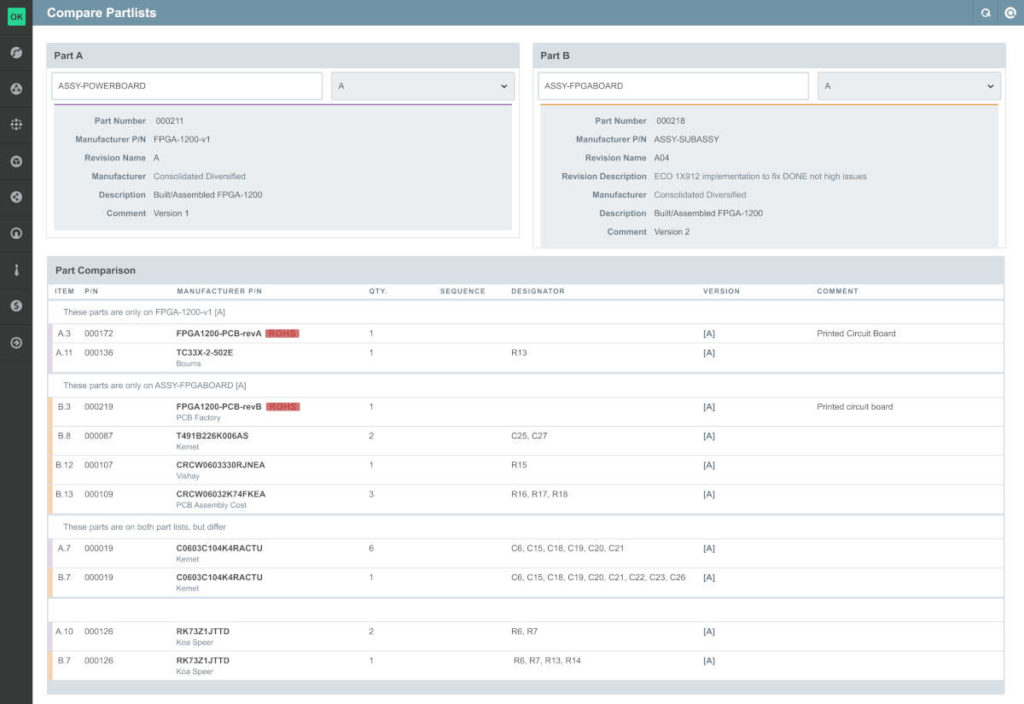

Easily Compare BOMs

Part lists can get lengthy and detailed. If you’re managing different versions of lists, it can be easy to miss important specifications. Making sure the differences are denoted between build versions can be an exercise that’s best left to software. Aligni has a built-in function that makes comparing bills of materials simple. This functionality can automatically search both BOMs and their sub-assembly lists to determine which parts are missing or specified differently.

These are just a few of the ways Aligni can help manage complicated bills of materials. Take Aligni for a test drive and see how a purpose-built system can make your part management process easier. Sign up now!

Start your 30-day free trial

Helping You Make Great Things…Better.