Every aspect of supply chain management is important in making sure the firm can be as efficient as possible in converting its inputs into salable products. It’s important to give part and material lead times the attention they deserve when working to maximize production efficiency. Like many data intensive operations with a lot of moving parts, lead time management all but requires the use of purpose built software like an MRP system to be truly competitive in today’s economic environment. Here, we go into detail why it’s important to give focus to lead times and why using an MRP system, like Aligni to do it, is a supply chain manager’s best tool for the job.

Why Focus on Lead Times?

Reducing lead times offers significant benefits for supply chain managers, positively impacting various aspects of the business. Shorter lead times result in improved customer satisfaction by ensuring timely order fulfillment and on-time deliveries. Additionally, it enhances responsiveness and agility, enabling supply chain managers to adapt quickly to changing customer demands and market conditions. Moreover, reducing lead times helps optimize inventory levels, minimizing holding costs and efficiently utilizing production resources. It also mitigates the risk of stockouts, strengthens supplier relationships, and fosters better supply chain visibility. Faster lead times can lead to a competitive advantage, attracting more customers and speeding up time-to-market for new products. Ultimately, lead time reduction contributes to enhanced operational efficiency, increased cash flow, and aligns with sustainability goals, making it a crucial strategy for supply chain optimization and overall business success.

Common Lead Time Reduction Tactics

Industries, products and markets can all have their own procurement needs and processes. There are some reduction methods that can be shared across different markets. Let’s delve into more detail for each of the lead time reduction areas for supply chain managers and the major tactics they could employ for each:

1. Increasing Supplier Collaboration

- Establishing stronger relationships: Build collaborative partnerships with key suppliers based on mutual trust, transparency, and long-term commitment.

- Joint planning: Work together with suppliers to forecast demand, plan production schedules, and align inventory levels. Sharing information can lead to more accurate planning.

- Getting vendors involved earlier in the process: Engage suppliers early in the product development process to reduce lead time in obtaining prototypes and initial production samples.

2. Get Analytical with Vendor Management

- Set up performance metrics: Set clear performance metrics, including lead time targets, for suppliers and regularly evaluate their performance against these metrics.

- Maintain supplier scorecards: Use supplier scorecards to monitor and track key performance indicators (KPIs), such as lead time adherence, on-time delivery, and quality.

- Conduct Performance reviews: Conduct regular supplier performance reviews to address issues and find opportunities for improvement.

3. Forecasting and Demand Planning

- Historical data analysis: Use sales data, customer orders, and market trends to forecast future demand accurately.

- Collaborative forecasting: Engage sales and marketing teams to share market insights and customer feedback to improve forecast accuracy.

- Demand smoothing: Reduce demand fluctuations through promotions, incentives, or demand management strategies to provide suppliers with more stable forecasts.

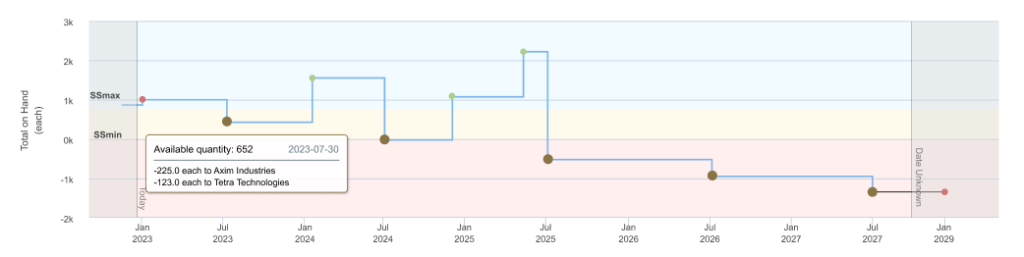

4. Safety Stock Optimization

- Lead time variability analysis: Examine historical lead time variability to determine the appropriate level of safety stock needed to account for unpredictability.

- Inventory modeling: Use inventory optimization tools to simulate different scenarios and identify the optimal safety stock levels that balance customer service and inventory costs.

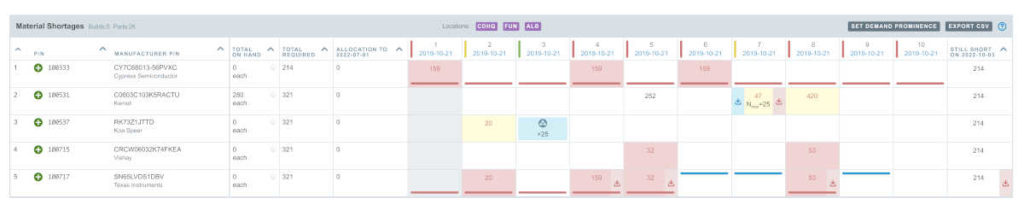

- Material prioritization: Identify critical orders or components and prioritize their production or delivery to meet urgent customer requirements.

5. Think About Transportation Efficiency

- Tracking and visibility: Use technology to provide real-time tracking and visibility into orders and shipments, enabling faster decision-making.

- Consolidation: Consolidate shipments whenever possible to reduce transportation costs and improve delivery schedules.

- Nearshoring: Consider sourcing from suppliers located closer to the manufacturing facility or target market to reduce transit times and lead times.

6. Practice Multi-sourcing opportunities

- Dual sourcing: Identify critical components or materials and establish relationships with multiple suppliers for these items to reduce the risk of supply chain disruptions.

- Supplier qualification: Ensure that alternative suppliers meet the necessary quality and reliability standards before incorporating them into the supply chain.

7. Perform Lead Time Benchmarking

- Industry research: Conduct research to understand industry benchmarks for lead times, comparing them to the organization’s current performance to identify gaps and opportunities.

- Best practice adoption: Adopt best practices from industry leaders to improve lead time performance and supply chain efficiency.

8. Develop Interdepartmental Collaboration

- Integrated planning: Foster collaboration between different departments, such as sales, production, logistics, and finance, to align efforts and coordinate activities effectively.

- Sales and Operations Planning (S&OP): Implement S&OP processes to align demand, production, and inventory plans across the organization.

Managing with the Right Tools

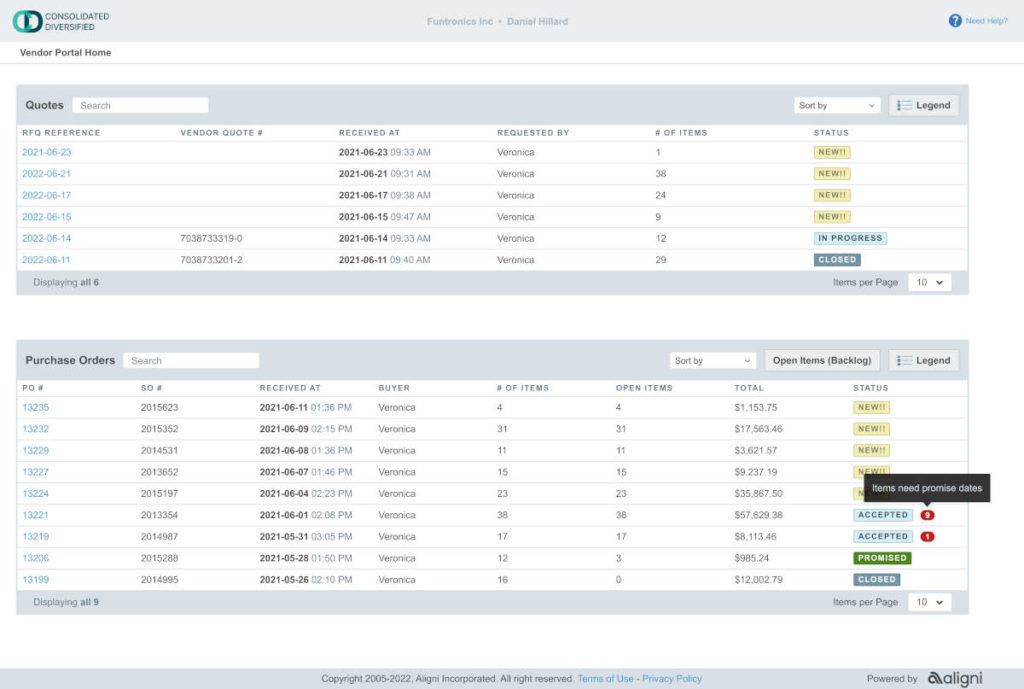

All these aspects require data and a great command over every aspect of a company’s supply chain. That’s where the benefits of using an MRP system comes in.

MRP systems make it much easier to develop accurate demand forecasting using historical data, customer orders, and other inputs. These systems enable supply chain managers to plan orders in advance and minimize delays. An MRP calculates precise quantities of raw materials and components needed for production based on demand forecasts and current inventory levels, ensuring timely procurement and minimizing material shortages. By generating production schedules aligned with anticipated demand, the MRP system prevents overproduction and ensures products are ready when needed.

Moreover, MRP systems facilitate better collaboration with suppliers by sharing accurate demand forecasts and production schedules. This helps suppliers plan their processes more efficiently, leading to reduced lead times. The system tracks lead times for components and materials, providing visibility into bottlenecks and areas for improvement. It helps supply chain managers optimize safety stock levels, striking a balance between avoiding stockouts and excess inventory. MRP systems also streamline order management, minimizing manual delays and errors, and support Just-in-Time (JIT) inventory principles to speed up order fulfillment.

Bringing It All Together

If you’re looking to get more out of the supply chain process, making materials available when needed, reducing stockouts, and aligning production with customer demands, skip the spreadsheets. Through next-level inventory management, supplier collaboration, and data-driven decision-making, MRP systems significantly contribute to lead time reduction and enhance overall supply chain performance – both for today and future growth.

Make the change to a purpose-built inventory management system, Aligni MRP.

Start your 30-day free trial

Helping You Make Great Things…Better.