Aligni for Production Managers

Effectively managing production operations means coordinating many moving parts to ensure everything runs smoothly. This requires seamless collaboration between teams, real-time visibility into processes, the ability to respond quickly to changes, – and the right tools to do it.

Efficiently Plan Production Builds

Production management requires precise coordination of resources, inventory, and schedules to ensure orders are completed on time. As your operation grows and the complexity of multiple builds with varying requirements increases, spreadsheets simply can’t keep up. The risk of errors, inefficiencies, and delays rises, making it harder to maintain control over your production process.

That’s where Aligni MRP comes in. Specifically designed for production managers in discrete manufacturing, Aligni MRP streamlines every aspect of your operation. From managing production builds to optimizing inventory and resource planning, Aligni gives you the tools and real-time visibility needed to run a more efficient, error-free operation. Don’t let outdated systems hold you back. Read on to learn more about how Aligni MRP can help you take full control of your production management.

For Build-to-Order Sales

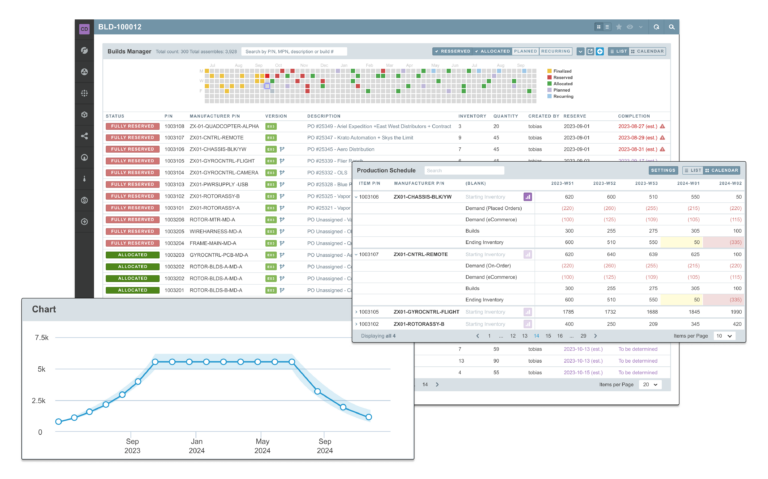

For production managers overseeing make-to-order manufacturing operations, Aligni MRP has functionalities designed to streamline and optimize the management of production runs tied to individual sales orders. The process begins with entering each sales order into the system as a distinct production build. This allows for accurate tracking and scheduling of these jobs.

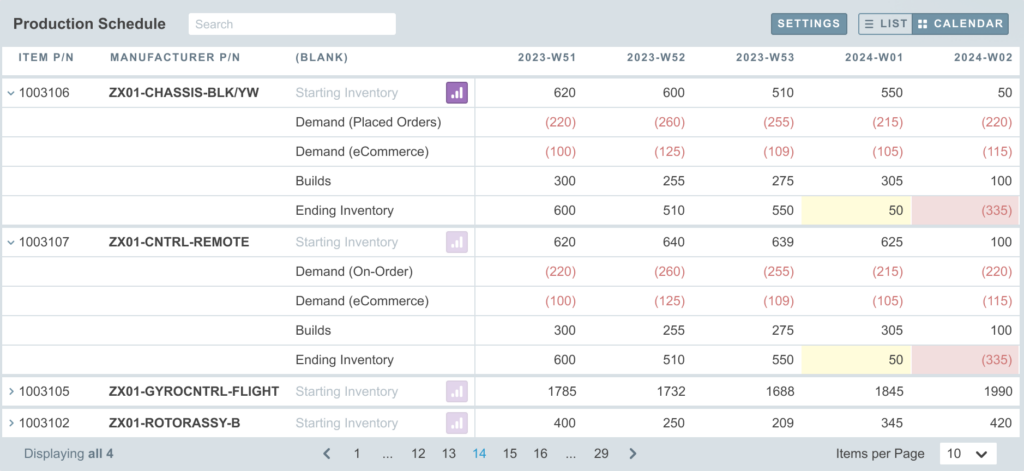

Unlike managing multiple disconnected spreadsheets, Aligni consolidates all production builds into one cohesive system, offering a complete and unified view of every production activity across the organization. This ensures that managers can monitor production status with real-time updates and make more informed decisions based on the current workload.

Once production builds are entered into Aligni, they are automatically linked to available inventory, providing immediate visibility into whether the necessary parts and materials are on hand to fulfill orders. In cases where inventory is insufficient, the system alerts the purchasing department to initiate procurement. This collaboration between departments helps prevent delays by addressing part shortages before they impact production schedules.

Using Aligni MRP, production managers can anticipate and resolve potential issues early, adjust schedules as needed, and ensure smoother operations. This proactive approach not only boosts production efficiency but also reduces the risk of costly disruptions in make-to-order manufacturing environments.

For Make-to-Stock

When sales quantities are low but overall volumes are high, a different sort of production management is needed – but that style is also well-managed by Aligni MRP.

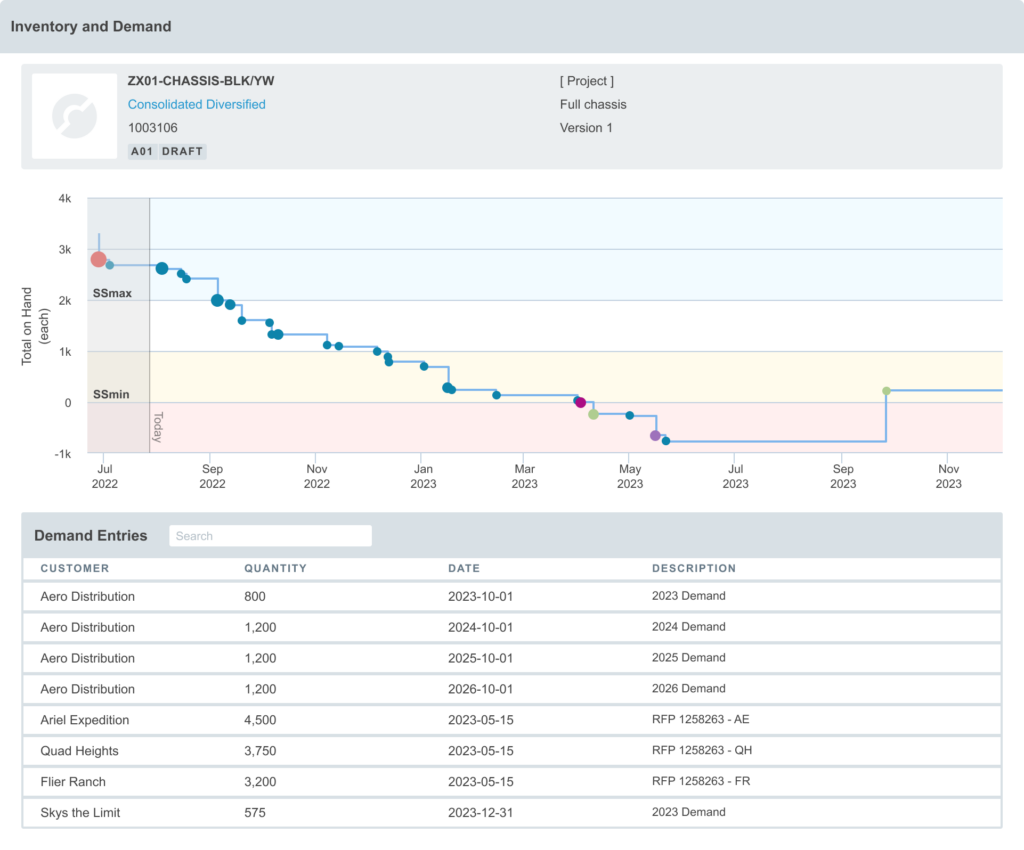

Using Aligni’s Production Calendar, production managers can gain comprehensive oversight of how demand impacts each product in make-to-stock operations, allowing them to make informed adjustments in real time. This tool provides a clear view of the relationship between sales-driven inventory depletion and production’s efforts to replenish stock, not only in the short term but also over extended periods. By visualizing this graphically, production managers can better understand how current demand aligns with production capacity.

The Production Calendar also incorporates user-defined parameters such as overstock and safety stock thresholds, which are essential in maintaining optimal inventory levels. These thresholds help to minimize stockouts and prevent overproduction, ensuring that resources are allocated efficiently.

With this functionality, production managers can proactively manage production schedules, anticipate potential issues, and balance workload more effectively, even in eCommerce situations. This enables more strategic planning, reduces inefficiencies, and improves overall execution, allowing for smoother operations and better alignment with demand forecasts.

Learn more about Aligni’s Build Manager and Inventory Outlook

Plan for the Long Term

The next level of production management involves looking beyond immediate needs and planning for long-term growth and future opportunities. Aligni provides the production manager the advanced tools necessary to move from reactive day-to-day management to a more proactive, strategic approach.

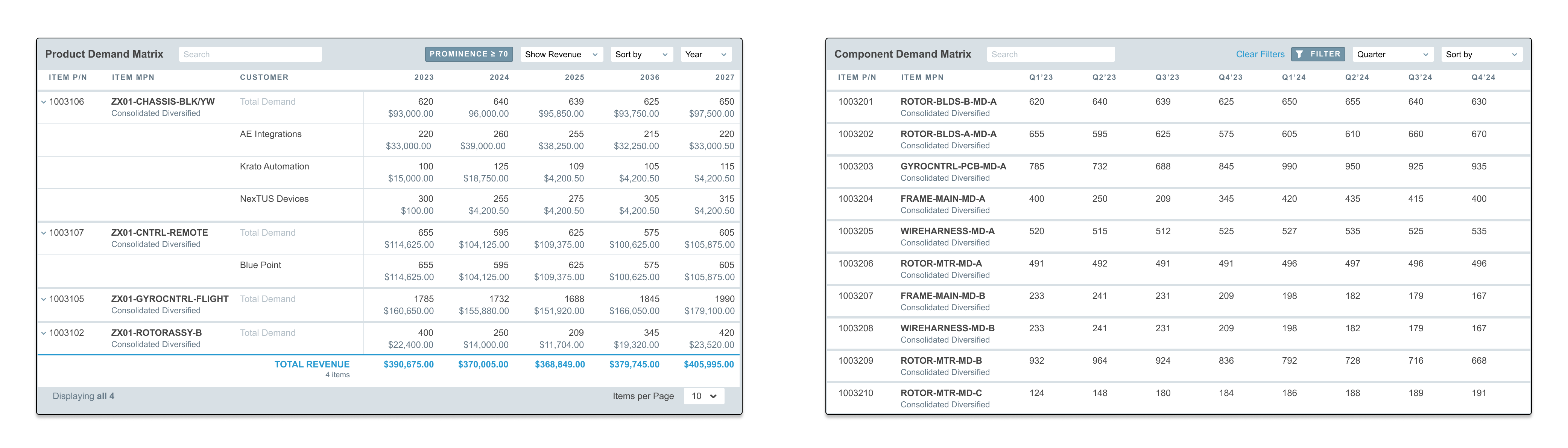

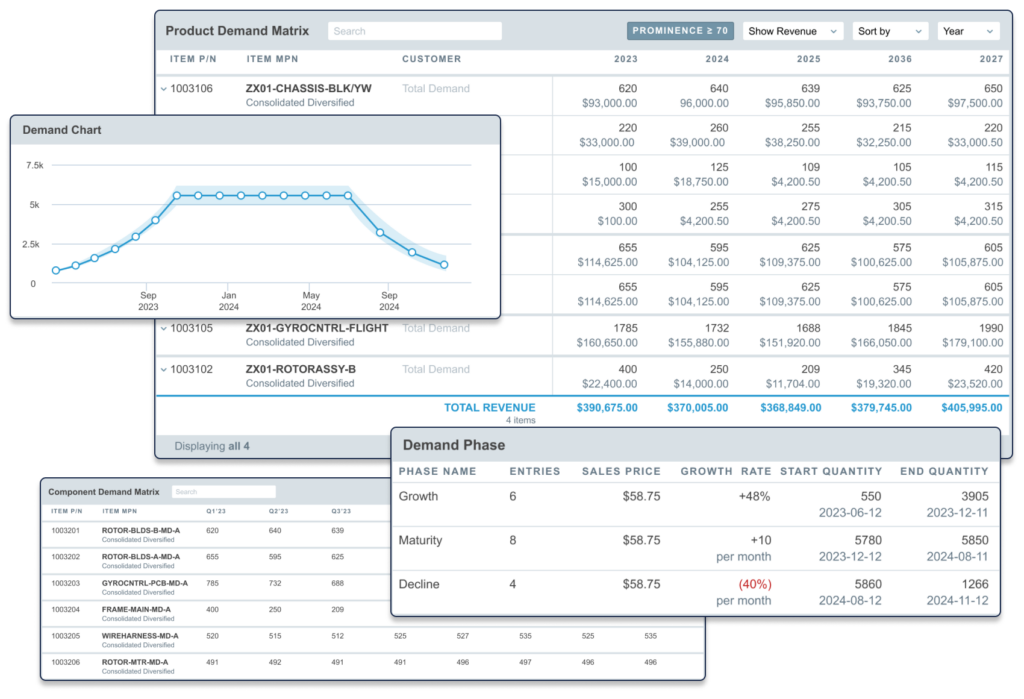

With Aligni’s Product Demand matrix, managers can forecast orders not just monthly or quarterly but across yearly schedules. This longer-range view provides managers a comprehensive view of future production needs. Combining the Product Demand matrix with the Component Demand matrix allows managers to assess the long-term requirements for parts and materials, helping managers make informed decisions on capital expenditures or strategic vendor partnerships.

Aligni’s Flow Demand forecasting tool takes this further by giving production managers more control and flexibility in estimating future customer demand. With this tool, forecasts can be broken down into phases, each with its own product demand and growth rate, allowing managers to create more accurate, realistic predictions. These forecasts can account for fluctuations in demand due to seasonality or changes throughout a product’s life cycle, ensuring that both increases and reductions in demand are considered. This level of granularity enables production managers to better prepare for future needs, optimize resource planning, and ensure the right balance of inventory and capacity for sustained success.

Learn more about Aligni’s advanced forecasting functionalities

Explore what Aligni can do for your organization

Stay Informed and In Control with Real-Time Collaboration and Custom Alerts

Producing products in a dynamic environment requires agility as customer requirements, part availability, and demand can shift unexpectedly. For production managers, staying informed and in control of these changes is critical to maintaining smooth shop floor operations. Aligni MRP provides the intelligence and tools needed to keep managers updated in real-time as these changes happen, ensuring they have the insight necessary to make informed decisions.

Aligni offers customizable alerts for when key conditions, such as inventory shortages or low safety stock levels, arise. These notifications also extend to change management activities, ensuring that production managers are always aware of factors that could impact shop floor processes.

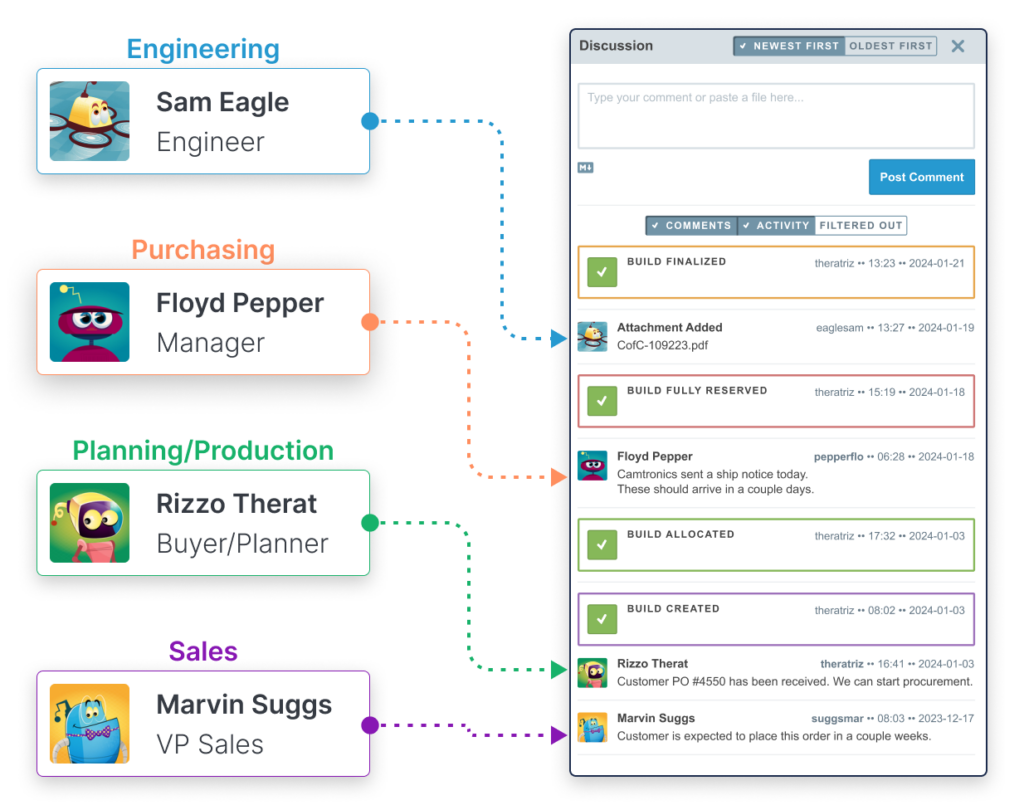

Additionally, Aligni’s DiscussAnything feature enhances collaboration by allowing managers to actively participate in discussions surrounding changes, understand the reasoning behind them, and ask critical questions. This integrated communication fosters stronger departmental collaboration and enables managers to be more proactive, addressing potential issues before they disrupt operations.

Learn More About Aligni

Managing a production operation involves coordinating resources, inventory, and schedules across departments to ensure orders are fulfilled on time. As production scales and complexity increases, relying on spreadsheets becomes inadequate, leading to errors, inefficiencies, and communication gaps between teams. Aligni MRP addresses these challenges by providing a centralized platform for production managers.

Aligni MRP not only streamlines production builds and optimizes inventory management, but also fosters real-time collaboration between departments, such as purchasing, production, and inventory management. This enables teams to work together seamlessly, ensuring that everyone is aligned and working with the most up-to-date information. With its powerful tools and visibility, Aligni MRP allows managers to move beyond the limitations of spreadsheets, ensuring efficient, error-free operations and improved cross-departmental coordination.

Sign up today or try the demo to get a deeper understanding of what Aligni MRP can do to enhance your supply chain operations!

Start your 30-day free trial

Helping You Make Great Things…Better.