Smart Software for Buying Parts & Building Products

Enterprise-class tools for procurement, inventory & build management, and vendor collaboration built for growing small- and mid-sized businesses.

Meet Your New Production Management OS

From design to manufacturing, Aligni is your home base for efficient planing, execution, and monitoring.

- BOMs and Revisions

- Change Management

- Inventory

- Production

- Procurement

- Material Planning

- Supplier Relations

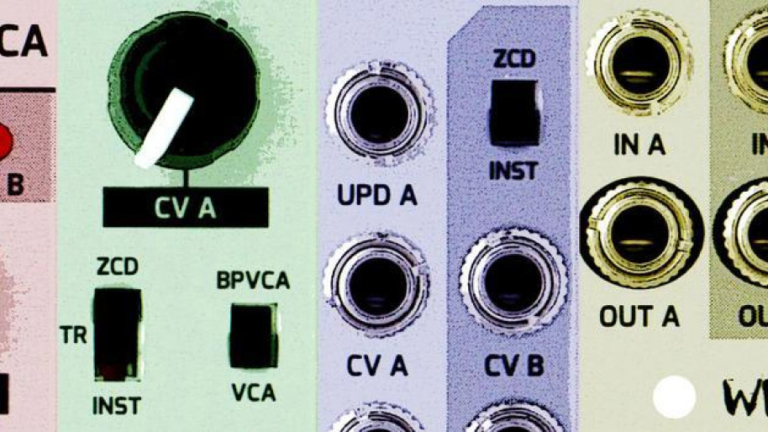

Unlock efficient engineering with Aligni’s simple and intuitive BOM and revision management. Gain a 360º perspective on your projects with features such as seamlessly-integrated change request and change order iterations and where-used visibility for all of your components.

Track what goes into your products, who supplies them, what’s on-hand, and what they cost.

Aligni is source-code management for your hardware.

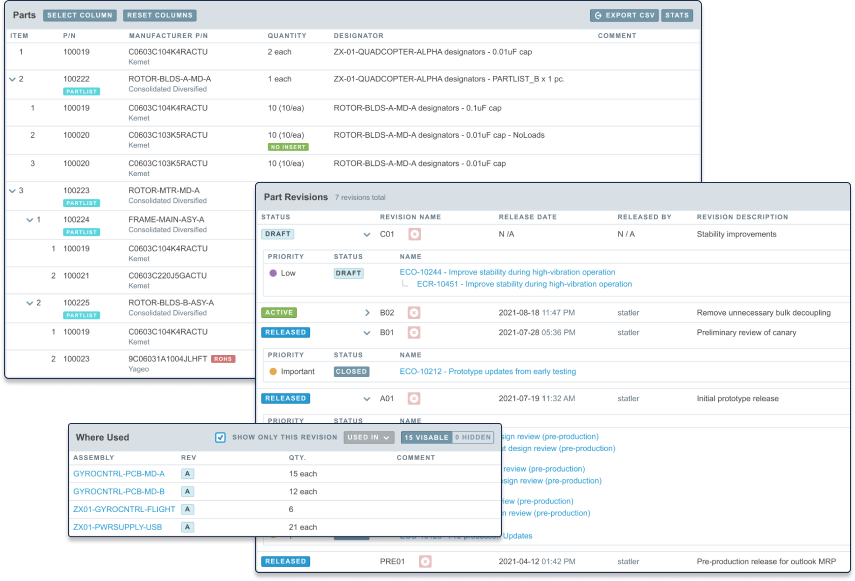

Gain confidence that everyone is on the same page. Discuss, track, and understand BOM changes with Aligni’s built-in Engineering Change Management (ECM) functionality.

With integrated MRP and PLM, engineering and production have common item master visibility and can see past and pending changes with clarity. Share knowledge and history with current and future team members, on record, without relying on email.

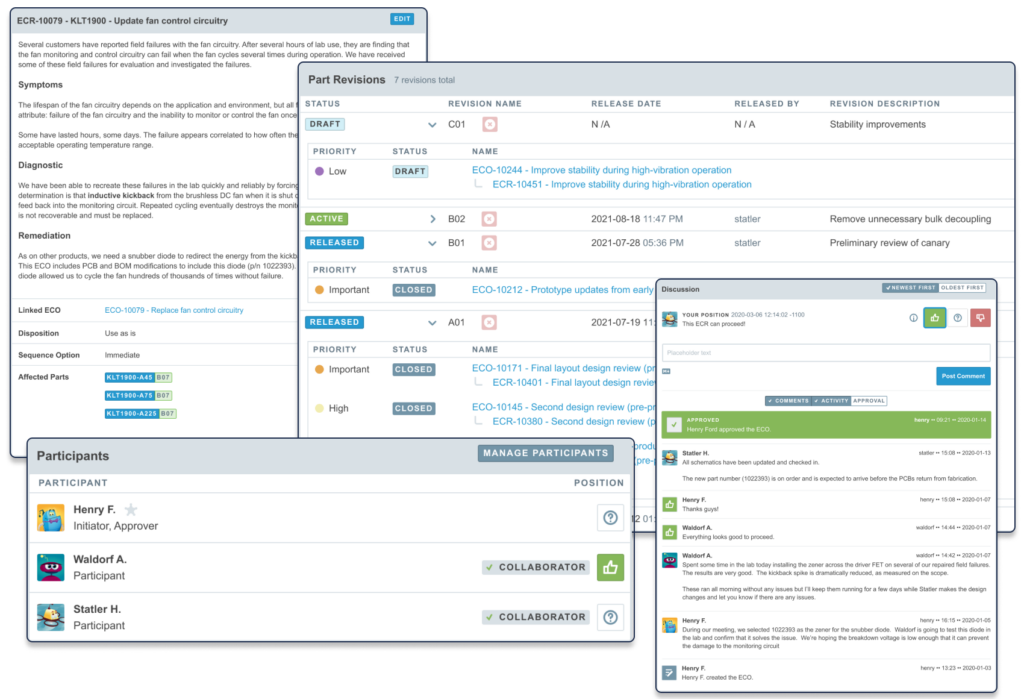

Aligni provides unparalleled perspective on what you have, what you need, what’s on order, and what’s being used. Our inventory outlook view integrates current inventory quantities, sales forecasts, procurement operations, order lead times, and build consumption. You can manage it all within Aligni’s easy-to-read, annotated forecast visualizations.

The safety stock manager lets you establish per-part safety stock levels for each of your warehouses. And don’t sweat the lead times. Use the TimeWarp™ feature to easily navigate varying lead times to prevent line-down situations while controlling holding costs.

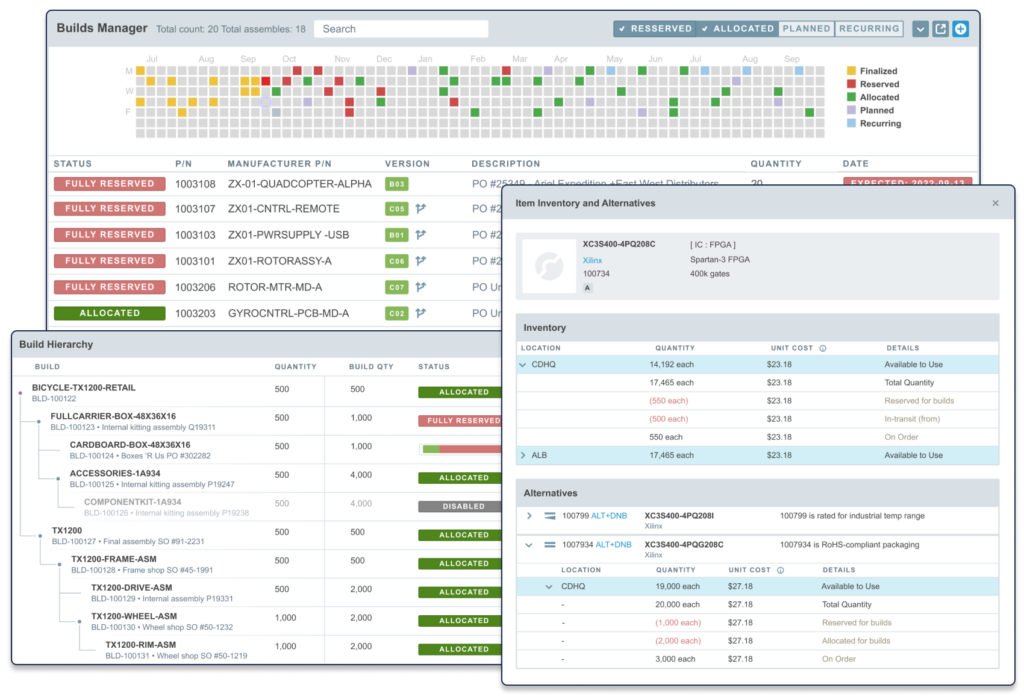

In high mix, low volume environments, it can be difficult to manage production needs. Aligni has the tools to schedule parts and materials around changing customer demands, find alternate components when necessary, and manage fluctuating production quantities – all through its build management capabilities.

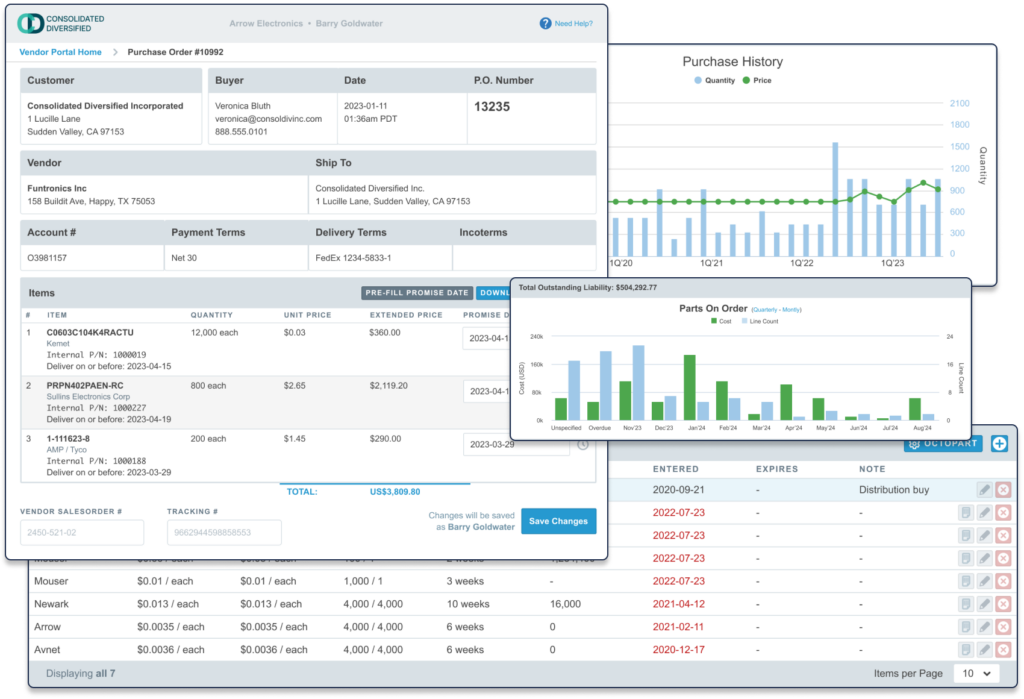

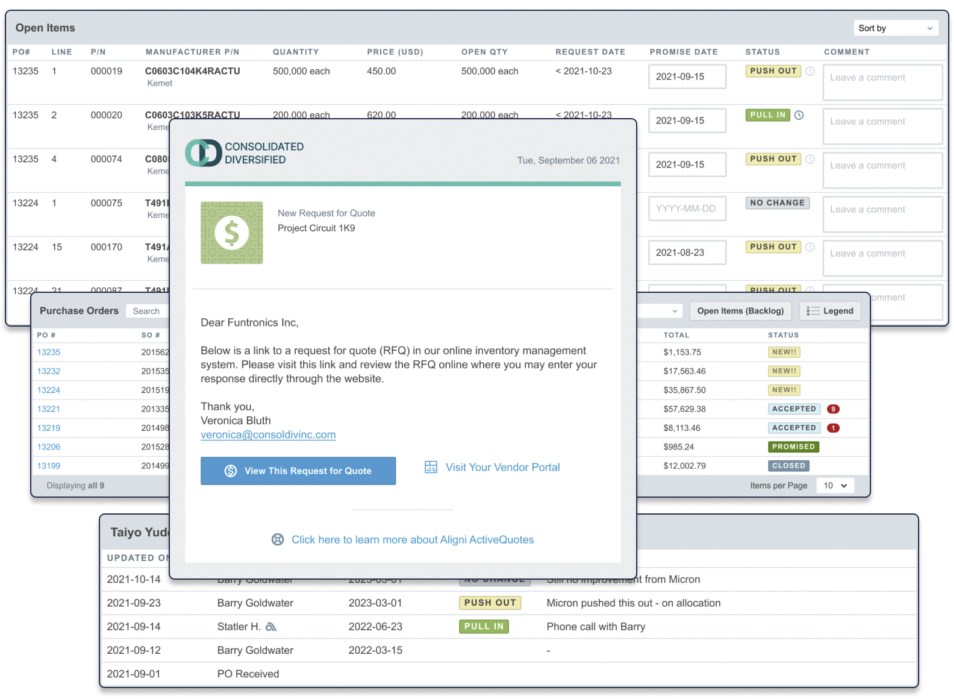

Integrated quoting and purchasing tools enable buyers and engineers to buy directly from your BOMs and material shortages. Access to historical pricing and quantity details to make fast, accurate decisions. Parts-on-order are fully integrated into inventory and production forecasting tools for better planning and visibility.

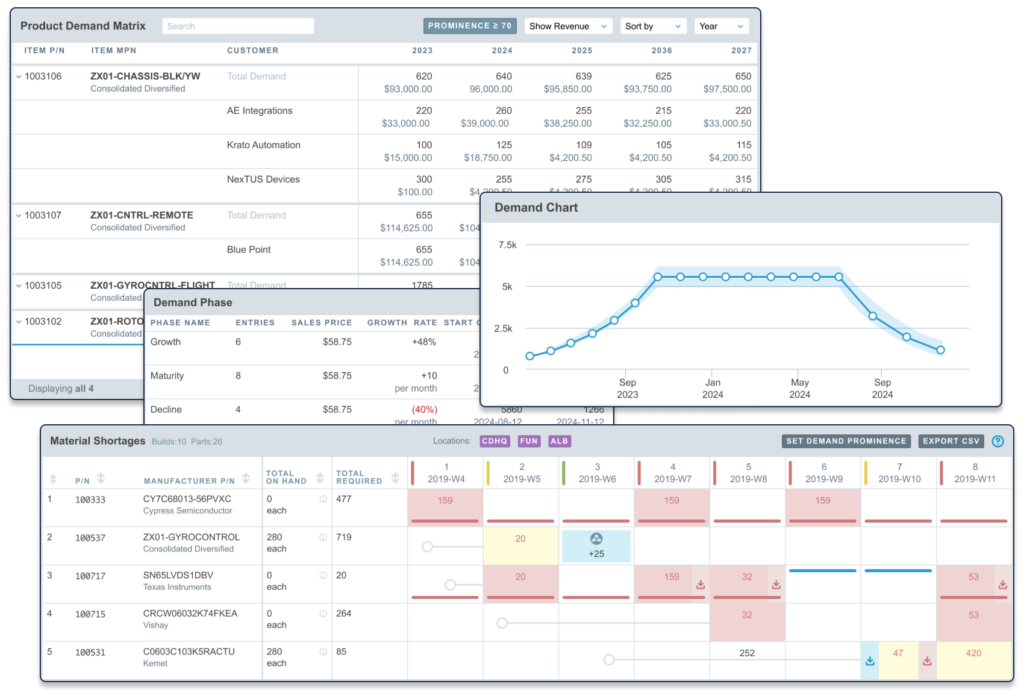

Advanced material planning features like demand forecasting, safety stock management, lead-time sorting, and highly-configurable material shortage reporting allow you to extend your planning over longer horizons with ease.

Keep production moving, reduce overstock, and impress vendors with savvy practices for better pricing and smooth delivery schedules.

Aligni’s purchasing tools provide the ability to send RFQs and purchase orders (POs). It also tracks and stores vendor responses, as well as connecting parts in use and alternates to preferred vendors. That makes it easy to not only see the status of current orders but utilize previous purchasing data to gain insights on pricing, availability, and vendor performance.

Improve Your Operational Intelligence

Make better and faster decisions.

Material Shortage Report

Quickly understand what’s needed and when with Aligni’s material shortage report, an insightful visual overview into the inventory conditions for all current production builds that drives procurement to keep production moving.

Learn more about material shortages

Estimate Demand

Stay ahead of production needs and avoid stock outs with Aligni’s demand estimation tool. Be proactive in scheduling part and material orders.

Learn more about demand estimation

Manage Safety Stock

Manage safety stock levels at multiple warehouses. Effectively forecast into the future for advanced planning use TimeWarp™.

Learn more about safety stock management

Insight, Foresight, and Hindsight

Powerful tools to manage your inventory from RFQ to production.

Integrated RFQ and PO Management

Save time, reduce errors, and execute like the pros: Issue RFQs and POs to vendors directly from Aligni so you have more time to focus on building great products.

Learn more about procurement with Aligni

Inventory Outlook

Easy-to-ready, graphical depictions make it easy to manage current inventory, build production consumption, and demand estimates across a single or multi-warehouse operation.

Learn more about inventory forecasting

Historical Purchasing Data at Your Fingertips

Keep track of every quote and every purchase of every item. Identify trends and understand supplier performance to operate at peak efficiency.

Learn more about procurement with Aligni

Collaborate Effectively with Shared Data

Increase operational speed and efficiency while reducing costly errors by consolidating information in one app.

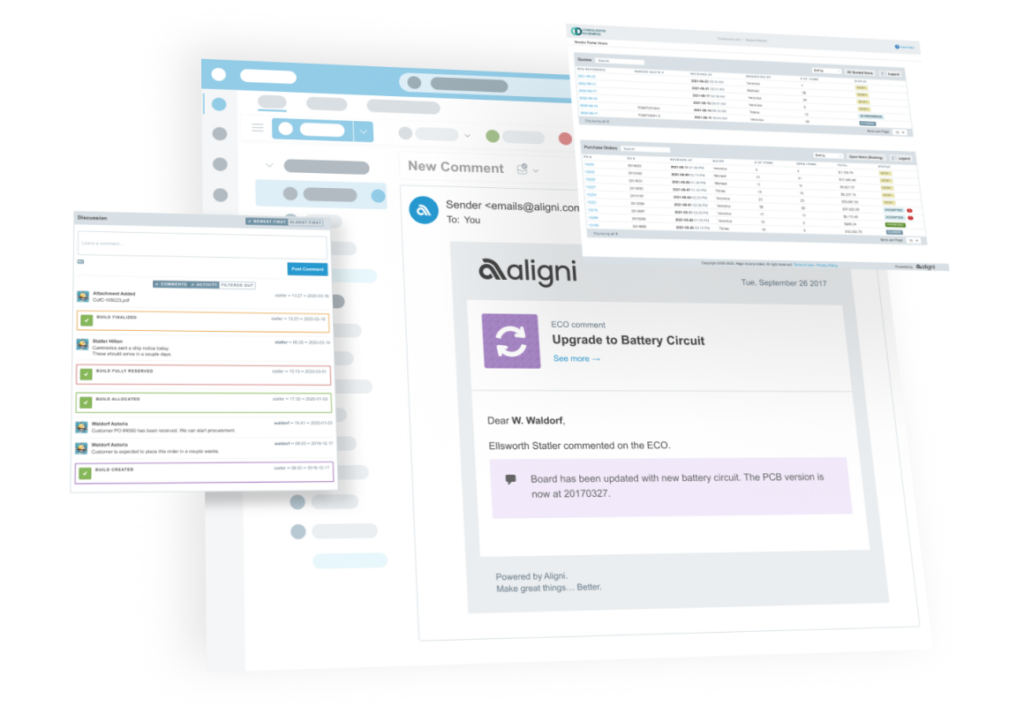

Communicate in-context with colleagues with DiscussAnything™ – a searchable database of context-specific discussions located directly in Aligni with the corresponding records: parts, builds, inventory transfers, purchase orders, RFQs, equipment, and more.

The Complete Package

All the tools you need to effectively manage your inventory and supply chain processes

Choose the Right Aligni for you

Let’s make sure you choose the right plan that suits your needs

Will suit you the best if you need to:

Will suit you the best if you need to:

Case Studies

Real Results, Real Success Stories

Explore how our solutions have made a difference for our clients

tadoº

WMD

Applied Information

SolVIS Automation

Backcountry Access

Start your 30-day free trial

Helping You Make Great Things…Better.